Aquafarming Is Not New

Aquafarming in water treatment has been around for thousands of years, and many cultures have depended on obtaining their resources from the sea or man-made water structures. Everything from fish farming to the growing of rice is a version of aqua farming, and millions of people every day outside of the USA depend on aqua farming in order to feed their families.

With the expansion of the industry and the commercialization of aqua farming, many products like salmon, catfish, and tilapia, to name a few, comes the need to improve the technique and technologies to improve the rate of the harvest and the quality of the product. Safety and the need to meet more stringent regulations in the US also play a major role in the commercial aqua farming business. High standards are placed on aqua farms to ensure that commercially grown and harvested products are free from all contaminants, diseases, and harmful bacteria that might endanger public safety. The need to control disease and bacteria is a major focus in the aquaculture industry because if it occurs, it can quickly spread to all other tanks or ponds, causing major losses and increased risks. Now with the United States entering the marketplace in aqua farming and with additional globalization occurring at a rapid rate, the land base aquaculture business operations and investments are outpacing the wild-caught production.

Salt-Brackish-Fresh Water

DeLoach Industries specializes in designing and constructing customized water degasification systems for pisciculture. They also offer decarbonation air stripping tower systems, pressure filtration systems, and disinfection systems such as U.V. light systems operating at 254 nm. DI can remove hydrogen sulfide (H2S), carbon dioxide (CO2), ferrous iron (Fe+), calcium carbonate (CaCO3), and manganese (Mg). In addition, DI can provide total control over pH, total suspended solids, and total dissolved solids to ensure high purity of water. When water purification is required by reverse osmosis or membrane filtration, DI can provide a complete package system with flow rates expandable into millions of gallons per day.

Often the water for seawater aqua farming is either pumped from the sea or obtained from the installation of brackish water wells with water quality levels ranging from 20-25,000 TDS or, if placed closer to the sea levels, can reach 35,000 TDS. One way water is treated and safeguarded in aqua farming is to pump the water to a treatment location where the pH is first properly adjusted. If the water is from the sea or brackish water well from the Florida region or the Caribbean, it may contain higher than normal levels of sulfur or hydrogen sulfide (H2S), which is a naturally occurring contaminant but can be detrimental to fish products that normally grow in other parts of the world where the water is without these conditions. The water is first injected with an acid-like sulfuric to adjust the pH to a 5 or 5.5 level, lowering the alkalinity as shown in the graph below. This will convert the sulfides into a hydrogen sulfide gas which can then be removed thru a process called degasification. The degasification process removes the hydrogen sulfide by using an air stripping process where the pressures are altered within the degasification tower. The science behind the process is based on “Henry’s Law,” which states that “dissolved gas is proportional to its partial pressure in the gas phase,” and the proportionality factor is called the “Henry’s law constant”.

Acid vs. Alkalinity

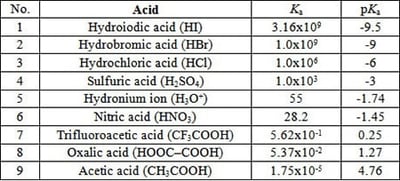

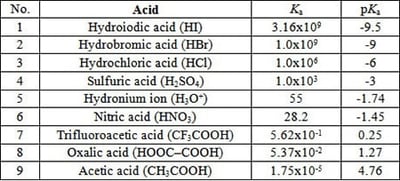

In addition to removing the hydrogen sulfide, the degasification process will strip and remove the carbon dioxide (CO2), and the pH will rise by 1-1.5. If removing iron in addition to hydrogen sulfide and carbon dioxide, the pH is often adjusted to 7, and after the oxidation process is complete within the degasification towers, DeLoach Industries recommends post-filtration through a series of pressure filters they manufacture. This will remove the oxidized iron to a level of 15 microns. If additional filtration is required, DeLoach Industries offers polishing filtration down to as low as 0.5 microns. Why maintain the same salinity level for aquatic sea life without adding harmful chemicals? Different acids have different values and strengths, as shown below in the table.

Other technologies, such as carbon filtration, can remove contaminants and impurities when aqua-farming freshwater species. Carbon absorption increases the operational cost because of the need to regularly replace or regenerate the carbon, which is why it is not the most economical method of water treatment for aquaculture and should only be utilized in the final phase of treatment after the bulk of all contaminants have been removed more economically through degasification and filtration.

Temperature Control

Many aqua farm species require temperature control, much like any agriculture greenhouse requires temperature control. Depending on the desired seafood products to be aqua farmed and the location of the aquaculture facility, the water temperature might require altering by either raising it or lowering it. If the aqua farm produces a cold water species of fish, then land-based commercial operations will utilize chillers to lower the water temperature unless the water is being extracted in a cold climate location. In Florida, most aqua farm processes that are growing cold water species of fish utilize chillers to cool the water. If the aquatic species being raised for the market require warmer water, use of heat pumps or solar thermal and heat exchangers can be utilized to control the incoming or recirculating water. To remove excess heat, cooling towers or degasification towers can be utilized to lower temperatures. Most water treatment in aquaculture farm operations experiment with temperature control and lighting in hopes of accelerating growth rates which are predicated on the feeding habits of the species in lieu of the addition of adding hormones which have been traditionally done outside of the US. In addition, the solubility of carbon dioxide in water varies as the temperature changes, as shown in the graph below.

Disinfection of Water

The need to safeguard aquaculture species from bacteria requires some disinfection procedure that will not have any negative or harmful impacts on the aquatic life that is being aqua farmed. The most effective and recommended method by DeLoach Industries is to utilize ultraviolet to treat and prevent bacteria within the water process. The initial feed water should be treated to kill harmful bacteria spores smaller than 0.5-1.0 microns or if polishing filtration is not performed. This will initially ensure that you are not introducing bacteria at the beginning of the aquatic process. Safeguarding the water and tanks is also important if aqua farming is conducted on land in man-made tanks or lined ponds.

With unlined ponds, the risk of bacteria and disease increases dramatically due to many variables that cannot be controlled, such as the accumulation of waste products. In addition, open, uncovered tanks and ponds are susceptible to contamination by birds and other forms of wildlife that may come into contact with the aqua farming process. The tanks and ponds must be kept clean to prevent the formation of harmful bacteria and diseases that can quickly spread to the other tanks or ponds if left untreated. The use of closed-in aqua farming processes provides better control conditions to safeguard against the introduction of bacteria and disease, and properly designed farms allow for the quick isolation of tanks should one become infected with a bacteria or disease, safeguarding the other tanks and aquatic life. By utilizing U.V. (Ultraviolet Light) at a 254 nano-meter wave strength, you can treat the incoming or recirculating water without the introduction of harmful chemicals. It is best to take these extra precautions first on the incoming water and any recirculating water systems. When possible, having a straight-through single-pass flow system is ultimately the best way to help prevent the introduction of bacteria and the spread of disease.

Major Species

|

Top 15 cultured fish species by weight in millions of tons, according to FAO statistics for 2013 [1]

|

|

Species

|

Environment

|

Tonnage (millions)

|

Value (US$, billion)

|

|

Grass carp

|

freshwater

|

5.23

|

6.69

|

|

Silver carp

|

freshwater

|

4.59

|

6.13

|

|

Common carp

|

freshwater

|

3.76

|

5.19

|

|

Nile tilapia

|

freshwater

|

3.26

|

5.39

|

|

Bighead carp

|

freshwater

|

2.90

|

3.72

|

|

Catla (Indian carp)

|

freshwater

|

2.76

|

5.49

|

|

Crucian carp

|

freshwater

|

2.45

|

2.67

|

|

Atlantic salmon

|

marine

|

2.07

|

10.10

|

|

Roho labeo

|

freshwater

|

1.57

|

2.54

|

|

Milkfish

|

freshwater

|

0.94

|

1.71

|

|

Rainbow trout

|

freshwater, brackish, marine

|

0.88

|

3.80

|

|

Wuchang bream

|

freshwater

|

0.71

|

1.16

|

|

Black carp

|

freshwater

|

0.50

|

1.15

|

|

Northern snakehead

|

freshwater

|

0.48

|

0.59

|

|

Amur catfish

|

freshwater

|

0.41

|

0.55

|

For more assistance or information on safeguarding your water or purification of the water, contact the professionals at DeLoach Industries Inc. at 941-371-4995. They can assist you in every aspect of water purification and can recommend the best available process for your particular aqua farming operation.