AI Controls Improve the Quality of Industrial, Food and Beverage, Commercial, and Municipal Water Treatment Plants and Pisciculture Products and Services.

Industrial plants are becoming increasingly automated because of the need for efficiency, safety, and cost-effectiveness. Artificial Intelligence (AI) plays a significant role in this automation process. AI has many forms, including stand-alone control panels or systems that can monitor or control a single device, an entire process plant, and all surrounding parameters.

The use of AI in industrial plants has many benefits:

- Allows the collection of standard data and additional data and parameters, analyses, and programmed decisions to reduce the risk of human error.

- Increases efficiency and lowers operating costs.

- Eliminating tedious and redundant duties often executed by facility or plant operators frees up valuable time needed for more critical operations.

AI can improve the safety of the plant for its workers. It can also help save money by optimizing resources and reducing energy consumption. As a result, AI has become increasingly integrated into our day-to-day lives as technology advances. As AI expands, our world moves faster and faster into the technology era.

Industrial operations such as semiconductors, oil and gas, and manufacturing typically have water treatment plants and processes. However, they have significant capacity needs with specific water quality requirements. Because of these factors, multiple treatment processes utilize hundreds of inputs and outputs for controls.

Using AI in these types of operations:

- Significantly reduced the employee's workload.

- Monitors system and processes systems in real-time

- Immediately reports any deviations or alarm conditions.

- Notifications and alerts can be instantaneous or even preemptive.

- AI calculates and predicts a failure or deviation and takes steps to alert or correct it in advance. Improving the quality of products and services for these processes has four main benefits.

Reduction of waste and costs.

Labor costs are rising, and cost reduction is one of the biggest challenges. In addition, due to the global pandemic, labor resources are at a record low status worldwide, causing millions of dollars in losses resulting from production delays. With AI, labor demand is reduced and even eliminated. As robotics moves from fantasy into reality, AI provides the solution to perform the daily task that previously was 100% relied upon by human intervention. The need to maintain their supply at an affordable price for the end-user. The quality management process requires tools and methods that are only generally available to some industrial producers. AI increases the quality of industrial water plant products and services. Companies can reduce the time, cost, and effort required to ensure their output is of the highest possible quality and lower their risk of failure.

Reduction of waste and improved traceability.

In addition to waste reduction, AI Control Systems can help monitor inventory levels more effectively than humans. For example, they can develop predictive demand levels to notify or execute raw material supplies during peak periods. Discontinue or reduce low-demand operations and overall monitor all levels of process from treatment to final destination. As inventory levels fluctuate during production, AI control systems automatically track these changes based on data from sensors throughout the factory as demand for more inventory is detected. AI systems can integrate increased water or wastewater treatment demand, allowing a controlled ramp-up of services to meet factory demands during production. For years, this type of information from one department to another was transferred either manually by person-to-person meetings or through inter-company emails. Now, AI provides the next step in the technology evolution by immediately communicating with other plant departments, calculating conditions, correcting problems, and taking prescribed actions.

Improves efficiency and reduces energy consumption for production.

AI relies heavily on instrumentation and sensors to monitor, detect, control, and notify during operations. Data collected throughout a facility or process plant is transmitted, processed, and analyzed within the AI system and operating software. AI can predict an increase in energy demand. If fully integrated, it can shut down non-essential systems. To accommodate increased power and to reduce overall energy demand and operating costs. The original AI systems are called "Building Management Systems (BMS). These systems have been operating for many years, controlling lighting, HVAC, fire and safety, and security. AI has evolved into more industrial processes, such as the control and monitoring of PLC, motor control systems, instrumentation, and AI. Its intelligent software analyzes all variables to calculate the most cost-effective solution and action to follow. If fully integrated, AI will execute the decisions to reduce labor, waste, and energy costs.

AI Increases the quality of production and reduces the risk of failure.

The quality management process requires tools and methods that are only generally available to some industrial producers. For example, when using AI to integrate building operations fully, inventory demands, production cycles, and increased and decreased water and wastewater treatment demands. It reduces waste, speeds up the execution of every task, lowers labor costs, increases the amount of information collected, and provides a more conclusive and informed decision regarding crucial operational parameters such as the operations of a water treatment plant or wastewater plant by implementing and integrating an AI system into a treatment process. Risk failure and failure analysis become fully integrated. Calculation of predictability will allow advanced preventative responses to prevent critical failures.

Maintaining Compliance

All water plant and wastewater plant operations must comply with their internal demands and regulatory rules and regulations set forth by the County, State, and federal levels. Failing to maintain compliance and abide by regulatory law can lead to stiff penalties and criminal prosecution for owners and plant operators with responsibilities and oversight control. With AI, an owner and operator are provided with another method to monitor, review, maintain, and report, and an advance alert will assist with any deviation or a predicted deviation. AI in critical processes can calculate and predict possible failures and take preventative actions before noncompliance. With Water and Wastewater treatment plants, there is always a potential for an accidental release or spill of chemicals that can create a toxic discharge into the environment. AI can assist by monitoring critical components and systems such as pumps, injectors, secondary containment systems, sensors, and instrumentation and alerting the owner or operator by alarm or even an automatic dispatch to a service technician to allow correction before any incident.

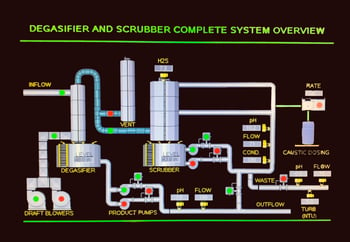

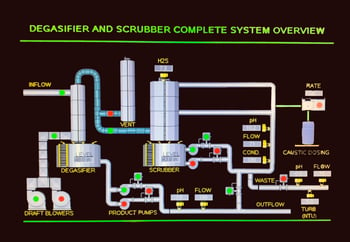

DeLoach Industries Inc. has been developing AI and integrating it into its different processes to serve its customers better. Systems such as RO, NF, and UF membrane treatment, Degasification, Decarbonisation, Filtration, Green Sand Filtration, Pump Systems, and Chemical feed systems can all benefit from AI technology. AI can provide an additional benefit in your treatment plant. Please get in touch with one of the professionals at DeLoach Industries who can help review your needs.