Converting Ferrous (Fe+2) (soluble) iron to Ferric (Fe+3) (Particulate/Solid form).

The iron must first be exposed to air or an oxidizing agent. Aeration System is the most cost-effective method to oxidize ferrous iron for its removal from water. In many areas around the globe, municipal and industrial operations need to remove naturally occurring iron (Fe) from the water to prevent damage to other equipment and improve water quality. Removing iron from the water must first be oxidized using the most widely accepted and cost-effective method called aeration. The aeration process changes the iron from its Ferrous (Fe+2) state (soluble) to ferric (Fe+3) colloidal participation. Did you know that Iron occurs naturally and is found in the earth’s crust? It occurs in both groundwater as well as surface waters and is not known to cause any harmful effects on humans or animals.

Iron does cause problems, though, for municipal facilities and their customers by impacting laundry operations and causing stains on buildings and on plumbing fixtures. Iron also promotes and facilitates the growth of iron bacteria in water, creating a problem for distribution lines and piping systems. Once the lines become blocked, this impacts the ability to distribute water to the customer. Iron bacteria also become detectible even at low concentrations and impact the taste of the water. The U.S. Public Health Service Drinking Water Standard set a recommended maximum level of 0.3 mg/L in public water supplies.

In industrial applications, iron can cause server damage in boiler systems.

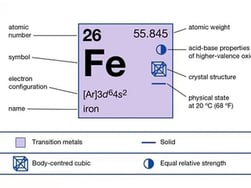

Cation and Anion systems, piping and nozzles, and other equipment. In addition, for other industries such as food and beverage, brewery, semiconductor, or the production of chemical products, iron can interfere with the manufacturing or brewing and canning process, lowering the quality of the final product. In groundwater and anaerobic surface water, iron is normally present in its soluble form called “Ferrous” iron Fe+2 when the pH is in a certain range. When the same water is in contact with air, that allows the air to diffuse into the water, or when any form of an oxidizing chemical is added to the water, the iron is converted into its oxidized form called “Ferric” Fe+3, becoming a solid. The ferric iron becomes visible and impacts the turbidity of the water and is typically not accepted by customers because the ferric iron within the water when in contact with surfaces, will create colloidal precipitates causing discoloring to all that it encounters over time.

What's the best and most cost-effective way to remove iron from water? Aeration!

There are various methods for treating and removing iron from the water process, which include Aeration, Filtration, Coagulation, and chemical oxidation. When treating water for iron, the inlet feed and outlet treated water quality is measured using either a standard analysis technique of atomic absorption, inductively coupled plasma, or colorimetric wet chemistry. In the municipal industry, colorimetric wet chemistry has been utilized for years; however, new techniques deploying UV wavelengths transmitted through water samples have been gaining acceptability. If measuring in online analysis, wet chemistry is the dominant method. Aeration utilizes a packed, typically square column to accommodate self-cleaning media manufactured by DeLoach Industries Inc. The packed column can be either induced draft or forced draft so long as no other harmful corrosive gases are present such as Hydrogen Sulfide (H2S), which would damage an induced type of blower system. When corrosive gases are also present or to be safe quite often, a “Forced Draft Aerator” will be selected. Water enters the top of the Aerator and travels downward by gravity as it then impacts layers upon layers of self-cleaning PVC slat trays. The PVC slat trays cause both the “impingement” of the water (reshaping) as well as breaks the surface tension by allowing the water to spread over the surface and expose the Ferrous soluble iron to air. As the Ferrous iron meets the air, it oxidizes quickly, forming ferric Fe+3 iron. The Forced Draft Aerator utilizes no additional oxidizing chemicals, which makes the Aerator the most economical and cost-effective method to convert Ferrous Fe+2 iron (Soluble) to Ferric Fe+3 iron and non-soluble particulate.

Once the iron has been converted to a Ferric Fe+3 (solid) state, it can be easily removed from the water by filtration, coagulation, and settling. Utilizing a DeLoach Industries “Forced Draft Aerator” with proper pH controls and a downstream, DeLoach Industries vertical pressure green-sand filters successfully remove the iron from the water process.

For professional assistance in designing a system for iron removal from water, degasification and decarbonation, contact the staff at DeLoach Industries, and they will assist you with every step of planning, designing, and implementing the most cost-effective water treatment method.