What is the difference between Aeration, Decarbonation, or Degasification, and which one is right for your water process application?

To answer this question, we first need to have a clear understanding of what benefits each of these (3) three different types of treatment processes for your water application.

- 1. The term Aeration means, to induce or maintain the oxygen saturation level in water in a natural state or an artificial one. When utilizing an Aerator you can expect to induce additional oxygen into the water stream that is passing through the system to the maximum saturation level possible at the current water temperature. As saturation levels will vary with water temperature it is important to always take the inlet water temperature into consideration. If your goal and objective are to remove iron as an example from the water process an Aerator unit should be considered and utilized as one of the most cost-effective methods of inducing oxygen and initiating the oxidation of iron. Converting Ferrous to Ferric iron then can be settled, collated, and filtered. Aerators manufactured by DeLoach Industries are NSF-61 certified and fiberglass compliant to RTP-1 standards and are available in a wide variety of sizes and materials. For heavy iron, magnesium, or calcium application the systems are available in a square design allowing for self-cleaning PVC slat trays to be utilized in place of loose fill media which will foul more frequently. Aerators are also available in a round tower design for non-iron applications to accommodate loose-fill media packing and are either a Forced or Induced draft configuration to accommodate applications where Hydrogen Sulfide may be present within the feed water to prevent corrosion from attacking the blower. The equipment can be manufactured from Fiberglass, Aluminum (depending on other contaminants), Stainless Steel, or rubber-lined steel and are available to accommodate flows from 5 to 4,500 GPM (gallons per minute).

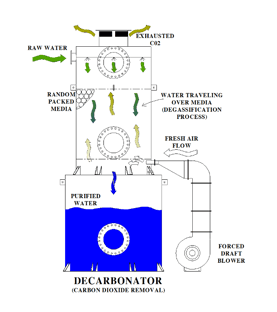

- 2. The process of Decarbonation refers to the removal of Carbon Dioxide (CO2) from water. CO2 can be naturally found in a water process or can be created from other elements such as Carbonic Acid which in the presence of water converts to free CO2. There are several reasons for removing CO2 from a water process which includes pH control, corrosion prevention, and reduction of operating costs when utilizing ion exchange for water softening. A Decarbonator is a piece of equipment that is manufactured specifically to remove CO2 from the water, and it is then exhausted through the vent located at the top of the unit. DeLoach Industries manufactures’ Fiberglass RTP-1 and NSF-61-compliant Decarbonators for water applications within the Municipal, Industrial, Food and Beverage, and Aquaculture markets. It is very common to utilize a Decarbonator post-membrane filtration, or prior to Anion and Cation treatment.

Similar to Aerators, Decarbonators are available in

- Aluminum

- Fiberglass

- 316L food-grade stainless steel

- Rubber-lined carbon steel

- 3. Degasification is a term that has a broader meaning and must be specifically applied to the process to be defined. The term “Degassing” can include the removal of oxygen, hydrogen sulfide, carbon dioxide, and other constituents. However, in order to remove oxygen then that specific process and equipment are referred to as “Vacuum Degasification” or “Thermal Degasification”. When utilizing a standard non-vacuum degasification process the system when designed properly will remove contaminants such as Hydrogen Sulfide (H2S) and Carbon Dioxide (CO2) effectively to 99.99% when pH and temperature adjustments are properly made. Degasification and Decarbonation are often used in a similar manner as they both refer to the removal of entrained gases from a water stream. DeLoach Industries Inc is one of the oldest and most experienced companies in the USA in the area of Degasification of water. A Degasifier is a type of treatment system like an Aerator or Decarbonator specifically designed to remove or induce gases into a water process application. Degasifier towers are typically designed and manufactured with RTP-1 FRP compliance or 316L Stainless Steel to accommodate higher corrosion exposure from the gases they remove. The forced draft is the standard design configuration for a degasification tower to prevent corrosive gases from damaging the blower and its components. Most membrane and reverse osmosis applications utilize degasification and decarbonation post-membrane treatment as the lowest and most efficient method to remove entrained dissolved gases and raise pH levels.

How do you decide which system to choose when designing or engineering your treatment process? DeLoach Industries trained personnel will assist all customers and their design professionals with the selection and design process. If you are in need of a degasification system for your commercial, industrial, or municipal water treatment use it is best to analyze several key factors.

What might influence your choice when designing degasification processes:

- Water Quality

Depending on the influent raw water quality prior to treatment and the desired effluent levels needed in the water stream a complete and thorough water analysis should be obtained and reviewed by the engineer and the equipment supplier.

Because there are several types of systems that each have different design configurations to accommodate raw water with high LSI scaling potential or fouling the review should take into consideration continued operational costs that may be needed for maintenance and cleaning. As an example, if the raw water analysis indicates an LSI reading that is negative and there are high levels of iron, calcium, magnesium, or other contaminants you will most likely make the decision to select a square Decarbonator or Degasification tower for the process. By selecting a square design unit you will have the option of selecting different types of media packing such as a non-fouling slat tray made by DeLoach Industries. Round degasifier only use a random pack or core pack type of media and have a higher fouling rate than slat tray media.

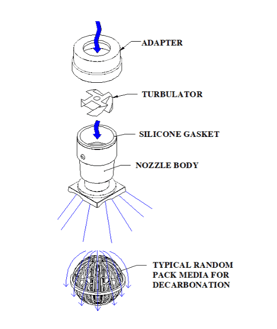

If the process is for a food and beverage application or other industry that requires higher ultra-pure water with low carbonation and contamination levels the use of a round packed decarbonator or degasification tower utilizing random packed loose-fill media will provide the highest removal efficiencies. DeLoach Industries designs and manufactures decarbonation towers for the food and beverage industry achieving 99.99% removal efficiencies.

If the process is for a food and beverage application or other industry that requires higher ultra-pure water with low carbonation and contamination levels the use of a round packed decarbonator or degasification tower utilizing random packed loose-fill media will provide the highest removal efficiencies. DeLoach Industries designs and manufactures decarbonation towers for the food and beverage industry achieving 99.99% removal efficiencies.

- Operating and Maintenance Costs

If Hydrogen Sulfide (H2S) or Iron (Fe) is present in high levels above 1-2 PPM then a “forced draft” type of decarbonation or degasification tower should be utilized to accommodate both the high corrosion levels of the gas as well as the ability to remove and clean the media easier. The forced draft unit provides additional protection for the blower from the harmful corrosive gases that are stripped from the water. Fresh air enters the blower located at the bottom of the degasifier in a forced draft unit and is discharged through the top exhaust or connected to a flange for further treatment of the gases. For water treatment that has Hydrogen Sulfide present, or CO2 avoid utilizing PVC material for the construction of the shell or other structural support items like the false bottom media support plates. Over time if PVC material is utilized the material will become brittle and crack or completely fail. The shell structures also will break down and become brittle if exposed to UV and or natural sunlight. Because of the turbulent flow and vibrations produced within a degasification process, the equipment experiences internal stress that PVC material over short periods of time tends to break or crack. The external shell and critical support structure components should be constructed of either Fiberglass, Stainless Steel or Aluminum, properly designing and selecting the correct Decarbonation or Degasification tower will provide higher removal efficiency and lower operating costs. For more information or to learn more contact the professionals at DeLoach Industries Inc. at (941) 371-4995.

Related Blog: How Degasification Can Solve Your Water Treatment Issues