Maximizing and adjusting the pH of industrial water for degasification and decarbonation.

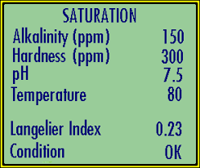

Industrial water treatment often requires the use of Reverse Osmosis membrane filtration to remove ions and solids in order to achieve the water quality needed for the industrial application. Sometimes the water is being utilized for the production of steam and prior to a boiler system, the water must be free from harmful elements that will cause scaling or corrosion. Other times water is treated to higher water standards because the water is being used in the process or even in the final product such is the case within the pharmaceutical industry or semiconductor market. In most applications it is often a requirement to adjust the pH of the water either prior to membrane filtration with reverse osmosis (RO) or after R.O. and prior to degasification. When applying pH adjustment prior to membrane filtration (RO) will help prevent membrane scaling during treatment. When performing degasification to remove dissolved gases like Hydrogen Sulfide (H2S) the optimal pH range is 5.5 prior to entering the degasifier. At a pH of 5.5, the water Langelier index is set at the peak levels to obtain full conversion and removal of the H2S from the water as a gas.

Adjusting the pH of the water is often needed and

when designing a decarbonation or degasification tower for industrial water treatment it is important to understand all the variables that go into a design in order to maximize removal efficiencies. Often, design professionals may not fully recognize the need to optimize the hydraulic load of an industrial treatment system. It is important to set the hydraulic load and pH at the correct levels when attempting to achieve a high level of removal and gain high efficiencies. Thought should be given to the relationship between the water process and its pH, the membrane filtration if applicable, and the type of media selection for a decarbonation or degasification tower. All media are not made alike and offer a variation of NTU and HTU values at different hydraulic load rates.

when designing a decarbonation or degasification tower for industrial water treatment it is important to understand all the variables that go into a design in order to maximize removal efficiencies. Often, design professionals may not fully recognize the need to optimize the hydraulic load of an industrial treatment system. It is important to set the hydraulic load and pH at the correct levels when attempting to achieve a high level of removal and gain high efficiencies. Thought should be given to the relationship between the water process and its pH, the membrane filtration if applicable, and the type of media selection for a decarbonation or degasification tower. All media are not made alike and offer a variation of NTU and HTU values at different hydraulic load rates.

When adjusting the pH of the water care should be given to also check the variations in hydraulic load versus performance. This will make sure your industrial water treatment system is operating at peak performance with the least amount of continued maintenance and chemical operating cost. If you are treating the off-gas emissions from your degasification tower to treat Co2 of H2S gases with a chemical control or biological control odor scrubber the pH in these systems becomes even more critical to system performance. Always discuss these variables with your O.E.M. suppliers before finalizing the size and hydraulic load of your system. Even though the capital cost may be less with a smaller system the results and operating cost could exceed your capital cost within a 1-2 year period if not designed properly. For more information or to learn more contact the professionals at DeLoach Industries Inc. at (941) 371-4995.