What is the best process for hydrogen sulfide treatment? Biological odor control Scrubber or a Chemical Scrubber?

Most industrial water treatment, municipalities, and private customers are responsible for water and wastewater treatment and often generate "hydrogen sulfide" off-gas odors. Professionals who either provide the design engineering or maintain the water or wastewater collection systems need to address and control "hydrogen sulfide" odors. They often find themselves in a situation where they must select what type of odor control system will perform for their customer or at their location. A chemical odor control scrubber may utilize "chlorine" or "caustic" as a scrubbing agent or just "caustic" alone. Typically, "acids" are not used when treating "hydrogen sulfide" gas, but "acid. " Acid is used when treating other types of off-gases such as ammonia. The application or process, including incorporating "artificial intelligence" into the machinery to provide more rapid responses to operators to predict maintenance and other operational functions—treating process air generated by either a "decarbonation" tower or a "degasification" tower for the removal of "carbon dioxide (CO2) or "hydrogen sulfide (H2S). It is important to understand the basics of either of the processes to allow the design professional to properly select the best type of "odor control" scrubber to utilize and make the decision to either select a chemical scrubber that uses "caustic" or "chlorine" or a biological scrubber for the treatment of the hydrogen sulfide that only requires the use of "caustic" to buffer the recirculation water. In other types of processes involving treatment, such as ion exchange, a design professional or owner must understand that the process may also produce an off-gas that requires treatment. "Ion exchange" can be used as a standalone treatment process to treat hard water utilized as a post-treatment process after reverse osmosis. Regardless of when "ion exchange" is utilized, we recommend removing the carbon dioxide (CO2) before the process to prevent the formation of carbonic "acid" and to extend and save the life of the Ion Exchange resin. It may also be necessary to adjust the pH of the water either pre or post-treatment by injecting either an "acid" solution when lowering the pH or injecting a "caustic" solution when raising the ph. It is important to remember that the efficiency of the process depends on proper pH control.

High pH and hydrogen sulfide will not convert or be removed by “degasification” and the “carbon dioxide” cannot be removed.

The process of decarbonation and "degasification" will also remove other types of contaminants from the water depending on if the treated water is for the upstream process. For example, the injecting of "caustic" to raise the pH in an attempt to make the water more "neutral," the design professional or owner should be aware that other contaminates that were previously in a dissolved state in suspension may begin to drop out as a solid during the raising of the ph. If the water is considered wastewater, then it may also contain. Other types of contaminants, including VOCs (Volatile Organic Chemicals), will be removed and stripped as a gas, and the other "degasification takes place to remove hydrogen sulfide or carbon dioxide. These off-gases often require treatment, and a design professional must decide to use either a chemical or biological process to neutralize the harmful and odorous gases.

The selection of what type of scrubber to use and what type is the most economical and operationally cost-effective is the challenge a professional or owner faces in addition to meeting the "air emissions" needs.

When choosing what type of odor control technology for any given application, variables are variables. The ability to remove the odor and neutralize the gas is often not the most crucial factor behind the technology selection. Several different methods of treating odors in water and wastewater applications, but this short overview focuses primarily on odor control gas scrubbers. The most prevalent types on the market today are either "chemical" or "biological" Both types have to utilize "caustic, chlorine, and in some cases acid as a chemical reagent or for pH control. Choosing what type of scrubber, it is best first to understand the parameters of the air waste stream you need to treat. Therefore, we recommend having the off-gas containing the "odor" analyzed by a laboratory to understand the total loading rate, the various contaminants, and what type of chemicals or reactions are creating the odorous or corrosive gases that need treatment. In addition, you will often find methane and hydrogen sulfide (H2S) combined with other organics, so understanding the chemical matrix of the gas is the first step in the selection process.

The next step is to make sure you gather more than just one sample over a more extensive period.

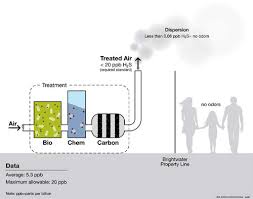

Critical in the selection of technology for odor control. If, after you collect your data, you see that you have concentrations that have wide variations over a day or even an hour with more than a 5% change, then a chemical scrubber utilizing either "chlorine" or "caustic" might be your best choice when treating hydrogen sulfide. Biological scrubbers perform best for treating "hydrogen sulfide" when the concentrations remain steady and do not fluctuate, and they only require "caustic" to buffer the recirculation water to maintain a pH close to neutral for the biological colony to thrive. However, when concentrations change rapidly, the biological growth cannot adjust fast enough, so the scrubber will experience a "break-through" of untreated gases unless it is a two-stage scrubber with a carbon polishing unit. Remember to monitor the pH of the inlet feed water because pH adjustment of industrial, municipal, or water requiring "reverse osmosis" can fluctuate, creating different removal efficiencies and load rates. On the other hand, if the gas stream concentration levels fluctuate, are incredibly high, or have a wide variety of compounds in the gas mixture, then a chemical scrubber (single or dual pass) is often the best selection.

The other two critical components of the selection process are the anticipated annual operating costs of the scrubber and what type of service will the scrubber receive.

In the past, odor control scrubbers are often met with challenges because they require constant attention and maintenance for necessary instrumentation that must function correctly. For example, DeLoach Industries is now incorporating "Artificial Intelligence" into their odor control scrubbers and "degasification/decarbonation" systems. The equipment is becoming more independent and will communicate directly to operators and owners, alerting them on routine maintenance to prevent critical problems or alert operators about the consumption of "caustic," chlorine, or "acid" chemicals. If the location of the scrubber is where there is no active operator, and it may be left unattended, then this can drive the decision back towards selecting a biological scrubber with fewer components that need maintaining. Therefore, it is always best to gather as much information on the specific location and obtain good analytical data before the final selection process.

If the odor stream is being pulled into the odor control scrubber, typically have a fresh air vent that allows makeup air to enter the tank. The proper balancing of the fresh air and makeup air to extracted air is critical as it may impact the concentration levels of the gases you intend to treat in the scrubber, which may influence the type of odor control scrubber you select. For more information or to learn more, contact DeLoach Industries Inc. professionals at (941) 371-4995.