What type of Odor Control Scrubber do I select?

Customers and design professionals frequently inquire about the most effective method for treating gases and odors in the Odor Control Industry. Selecting an odor control system is akin to picking a car, given the multitude of options available. We design each odor control scrubber with a variety of systems to cater to the diverse needs of the industry.

Customers and design professionals frequently inquire about the most effective method for treating gases and odors in the Odor Control Industry. Selecting an odor control system is akin to picking a car, given the multitude of options available. We design each odor control scrubber with a variety of systems to cater to the diverse needs of the industry.

Some scrubbers deal with ammonia smells, while others deal with acid. Choosing an odor control system is like choosing a vehicle, with many options available. We design each odor control scrubber in various systems to cater to the different needs within the industry.

For instance, engineers design specific odor control scrubbers to handle "ammonia" while they design others for "acid" off-gases. These scrubbers employ "acid" or "caustic" as the cleaning agent to counteract the off-gas.

Furthermore, odor control scrubbers differ in purchase prices and operating expenses. Odor control scrubbers employ either “acid” or “caustic” as the scrubbing agent to neutralize an off-gas. Furthermore, odor control scrubbers come at different purchase prices, each with varying operating costs. Always analyze the cost of the odor control solution, as different types of systems may work the same.

Different systems have varying costs for the equipment. However, it is crucial to take into account the ongoing operating costs when selecting an odor control system. How long will the scrubber I chose last before needing extra money for major repairs to keep it working? If you pick a hard or costly odor control system, you'll keep getting calls from customers seeking help and solutions.

The industry is undergoing new changes as it slowly incorporates "artificial intelligence" or AI into the wastewater treatment market. DeLoach Industries and other companies are using AI in their odor control scrubber products. This helps provide real-time information and data to owners and operators.

It can be challenging to select an odor control system that is both effective and affordable, despite the numerous options available. A designer should check the cost of chemicals used in an odor control system at each location. The price of "caustic" can differ.

The price of "acid" may vary due to differing foundational expenses or management costs and factors. Design professionals and suppliers must consider the challenges owners and operators will face in maintaining the odor control system. They should also assess the expected costs for daily operations and long-term service replacements.

Odor Control systems come in different types of processes.

Most manufacturers or sales representatives will recommend what they are most familiar with or what they sell. This doesn't mean the process types they say are the best won't work. It just means they might not be the best choice or the most cost-effective treatment. Let's take a moment to explore various odor control methods and their advantages and limitations.

The "masking agent systems" are not considered odor control scrubbers. They do not convert odorous or corrosive gas into neutral gas.

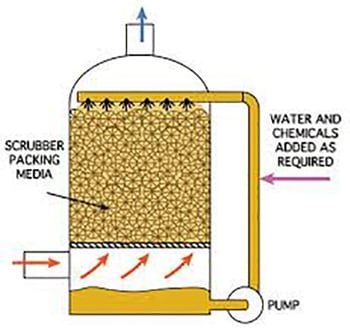

The "chemical scrubber" is a conventional odor management scrubber procedure that has existed for many years. This odor control scrubber uses several different types of chemicals to change and neutralize smelly gases, making them smell different.

Chemical smell scrubbers come in single or double-pass options and use alkaline or acidic substances to remove odors. Single or dual pass refers to one or two vertical mixing and reaction time columns.

Sometimes, it is necessary to use multiple towers in a row. Different types of chemical reactions are necessary to treat smelly gas like "hydrogen sulfide."

You must mix and interact the chemicals, such as "caustic and acid," with the gas. This helps to remove the smell or neutralize the corrosive gas. This is especially important when dealing with lower pH gas streams.

Assume that the concentrations of gas in the influent are sufficiently high. If the owner does not build the tower well for heavy use, they might need to pay for regular upkeep. This maintenance includes tasks such as cleaning and replacing media.

In the near future, artificial intelligence will be able to provide information about these costs. Artificial intelligence will soon be able to inform you about these costs. Apart from the extensive use of chemicals, the tower might also need to neutralize the foul-smelling gas.

At DeLoach Industries, designers utilize simulation models and calculations to examine foul or corrosive off-gas. They assess the preliminary investment cost of the machinery, its potential performance, and ongoing operational costs.

We acknowledge that the operating expense frequently surpasses the initial investment cost. There are different types of odor control systems. These include biological scrubbers for hydrogen sulfide, carbon absorption scrubbers for other VOCs, and chilled water scrubbers for either.

The experts at DeLoach Industries are ready to help you with your design needs. Feel free to contact us at (941) 371-4995.