In modern industrial water treatment, advancements in technology and processes have revolutionized the way contaminants are removed from water.

This blog explores the integration of NSF/ANSI 61 certified systems, artificial intelligence in water treatment, and cutting-edge processes such as decarbonation and degasification. We'll also discuss the key differences between forced draft and induced draft degasification towers, helping you make informed decisions while designing your Industrial Water Treatment System.

-

NSF/ANSI 61-Certified Water Treatment Systems: To ensure the safety and quality of water treatment equipment, NSF/ANSI 61 certification has become a crucial standard. This certification verifies that materials and components used in water treatment systems comply with health and safety requirements. When selecting a water treatment solution, opting for NSF/ANSI 61 certified systems guarantees peace of mind and adherence to the highest industry standards.

-

Harnessing Artificial Intelligence in Water Treatment: Artificial intelligence (AI) has penetrated various industries, and water treatment is no exception. Integrating AI into water treatment processes allows for more efficient and optimized operations. AI-driven systems can monitor water quality in real-time, predict system failures, optimize chemical dosing, and reduce energy consumption. By leveraging AI technologies, water treatment facilities can enhance their overall performance and streamline resource utilization.

-

Decarbonation and Degasification Systems: Decarbonation and degasification are essential processes in industrial water treatment, particularly in pH levels in water and the ability to control removing the contaminants. These processes target the removal of carbon dioxide (CO2) and other dissolved gases from water to improve its quality. Two key systems used for this purpose are the decarbonator and aeration system.

Read More

Topics:

degasification,

advanced treatment solutions,

biological scrubber,

NSF/ANSI 61,

Chemical Odor,

Decarbonation,

Safe drinking water,

De-Aeration,

decarbonator,

degasifier,

degassed water,

ansi61,

nsf/ansi61,

Deagasification,

decarbonation of water,

DeLoach Industries, Inc.,

Drinking Water,

Industrial Odor Control,

DeLoach Industries,

contaminants,

process system,

safe drinking water act,

drinking water standards,

environmental safety,

air emissions,

Forced Draft,

Induced Draft

Odor control in a manufacturing facility is essential.

It prevents potential health risks and discomfort caused by the spread of chemicals, vapors, and fumes. Additionally, excessive vapors can hinder the efficiency of exhaust and natural ventilation systems.

One effective solution for addressing odor issues is the installation of an Odor Control Scrubber Tower. These towers are part of the ventilation system in manufacturing plants and chemical processing facilities.

Odor control scrubbers help to remove noxious fumes and odors from exhaust and air streams. This is an effective way to improve air quality. This process involves utilizing an activated carbon filter and an ionic air filter

Key Considerations for Installing an Odor Control Scrubber Tower:

Health and Safety of Workers:

Industrial environments pose risks of exposure to hazardous fumes and gases for workers. Unhealthy odors emitted in high concentrations can jeopardize their well-being and safety. In some cases, these gases may even be combustible, adding an extra level of danger.

Odor control scrubber towers remove gases from the contaminated air, ensuring a safe working environment. These towers reduce the risk of health issues such as nausea, headaches, allergy symptoms, eye irritation, and loss of consciousness. This helps maintain worker productivity and prevents sickness caused by toxic fumes and gases.

Read More

Topics:

water treatment issues,

water quality,

odor control,

water treatment,

water distribution system,

advanced treatment solutions,

biological scrubber,

water plant,

safety,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

caustic,

Safe drinking water,

wastewater,

gases,

Biological Odor Control Scrubber,

Biological odor control,

what is a scrubber,

municipal water systems,

DeLoach Industries, Inc.,

Clean Water,

Industrial Odor Control

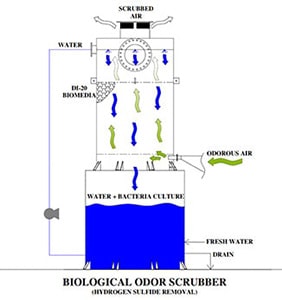

A Biological Odor Control Scrubber Is Just One Of Many Different Types Of Available Technologies to treat air emissions that may contain harmful gases.

This class of equipment commonly falls into a category referred to as “Odor Control Scrubbers” and they are utilized to remove dangerous or noxious odors from an air stream. The Biological Odor Control System has gained popularity among many end users such as municipal operators due to the reduced operating cost and more simplistic operating requirements. A typical chemical odor control scrubber often requires two or more chemical additives and more instrumentation is required to maintain system performance. With the additional chemicals required and instrumentation comes the need for more hands-on maintenance, calibration, and safety requirements which increases the operating costs and workload of the operator.

A Biological Odor Control System relies on active bacteria cultures that recirculate within a water stream and flow across a random packed media bed that is beneficial to the bacteria culture.

During the process of metabolizing harmful gases such as Hydrogen Sulfide (H2S) the biological odor control system requires only the addition of Caustic to control and balance the pH and additional water makeup to replace what has been consumed through evaporation or during the blowdown process to eliminate solids. There are several different types of odor control and chemical wet scrubbers, industrial air scrubbers on the market today and each provides a solution for the treatment of noxious or corrosive gases and odors in the industry. And even though Biological scrubbers are commonly utilized in municipal applications for the treatment of hydrogen sulfide (H2S) gases that were produced by a water or wastewater treatment process there are times when a Biological Scrubber does not provide the best solution for treatment. When there are wide or rapidly changing concentrations in the ppm (parts per million) level then a Biological Scrubber will have difficulties balancing and acclimating fast enough to prevent a breakthrough. As an example, In water treatment, there is a treatment process referred to as “degasification” which strips the hydrogen sulfide gas from the water, and then the concentrated H2S gas is exhausted from the tower through an exhaust port. When the concentration rises above 1 ppm for hydrogen sulfide gas then the levels become both noxious to the surroundings as well as corrosive. Many times, the levels range from 3-7 PPM in concentration with Hydrogen Sulfide and pose a serious health threat, noxious odor, and corrosive environment demanding capture and treatment. When utilizing an Odor Control Scrubber such as a Biological Scrubber the gases are pulled or pushed through an air duct system that is connected to the Biological Scrubber inlet or suction side of the blower. The same process is utilized when treating Hydrogen Sulfide (H2S) gases that were captured at a wastewater treatment process. These gases may have been generated from a source such as the wastewater treatment plant, lift station, or master head-works facility. When captured the gases are also conveyed in a similar manner to the Biological Odor Control Tower for treatment.

Read More

Topics:

water treatment issues,

degasification,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

media packing,

caustic,

wastewater,

gases,

H2S Degasifier,

Ammonia,

air emissions

Treating Hydrogen Sulfide for Environmental Safety

Read More

Topics:

odor control,

aeration,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

Decarbonation,

dissolved gases,

wastewater,

carbon dioxide,

degasifier,

gases,

Amine,

H2S Degasifier

Caustic solution for Sodium hydroxide water treatment of Sodium Hydroxide

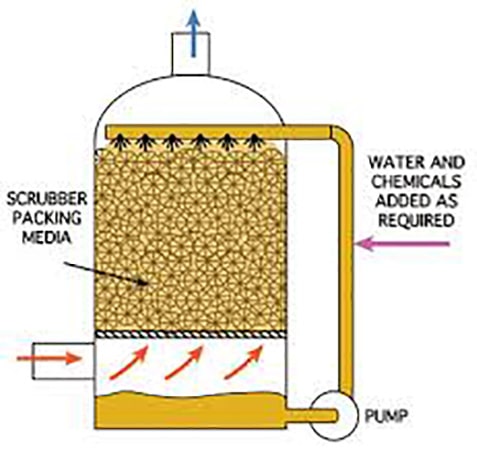

There are many industries that require the use of a caustic scrubber which is considered a chemical scrubber and they range from the municipal industry, mining, semiconductor markets, pulp and paper, and chemical refining. There is a wide variety of industrial processes that generate noxious or corrosive off gases that require treatment and a comparison is made between biological Vs. chemical. Often biological scrubbers have limitations due to concentrations, composition, or temperature of the contaminants and if the gas stream contains acid fumes then a biological scrubber is quickly ruled out.

The odor control selection is often fraught with choices of capital cost over operational cost and quite often comes down to familiarity from the designer or purchaser. It is always a good idea to freshen up the industrial odor control the do’s and don’t’s before selecting the final solution. If the off-gas source that needs to be treated is hydrogen sulfide (H2S) or some other type of gas stream produced by an acid or ammonia it will often require neutralization for human health reasons and to protect equipment or may be required to meet regulatory compliance. Caustic scrubbers may be either vertical or horizontal by design, but both utilize a packed media bed of either random packing or trays to allow the gas fumes to meet the recirculating caustic solution which then forces the reaction to occur.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

caustic,

wastewater,

carbon dioxide,

degasifier,

gases,

caustic solution,

sodium hydroxide water treatment

What type of Odor Control Scrubber do I select?

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

pH levels,

degasifier,

gases

Would it be possible for our odor control scrubbers to communicate with us and tell us when there are problems?

Or when they need service? With the new technological revolution, we are now this is quickly becoming a reality. DeLoach Industries is rapidly changing how water treatment and odor control and air emissions are treated with new advancements in artificial intelligence and integration into proven technologies.

Most operators will tell you that to keep and maintain an odor control system whether it's Biological Vs. chemical can be quite challenging depending on the type and source of the off-gas to be treated and depending on the type of chemical reagents being utilized such as acid or caustic solutions. When odor control systems such as a biological scrubber are met with varying flow rates, corrosive gases, or spiking concentrations an odor control system can be daunting to keep in balance and operating efficiency. But what if they could think or communicate with other devices or even operators for themselves? What if they could make corrections in caustic feed rates because of ammonia (NH3) concentration spikes, order chemicals like caustic or acid for pH control, and even inform us when they anticipate a problem for either the odor control scrubber or another critical component that it depends upon? That time has now arrived that’s to DeLoach Industries' new advancements to their equipment systems.

Read More

Topics:

degasification,

water distribution system,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

Decarbonation,

dissolved gases,

gases

A Biological Scrubber is a wet odor control scrubber that treats and removes contaminants from an air stream.

It utilizes caustic typically to control the pH of the re-circulation solution. There are several types of odor control and chemical fume scrubbers on the market today. Each plays a role in treating noxious or corrosive gases in the industry.

Biological scrubbers are used in municipal applications to treat low and high hydrogen sulfide (H2S) gas levels. This colorless gas is removed from the water or wastewater treatment process.

Water treatment equipment such as “degasification” or “decarbonation” towers.

Strips the hydrogen sulfide gas from the treated wastewater and exhausts the gas from an exhaust port. These gases are captured and sent to the biological scrubber via an air duct system. The health effects of hydrogen sulfide can cause eye irritation, loss of appetite, and fluid in the lungs. Hydrogen gases are captured at a wastewater treatment process, including treatment facilities, lift stations, or head-works facilities. The PVC or FRP duct system sends the gases to the biological scrubber.

How does a Biological Scrubber work?

A biological scrubber utilizes tiny microorganisms (bacteria) to break down and digest contaminants. The bacteria feed on the contaminants and utilize this as a feed source to live and grow. When utilizing a biological scrubber for hydrogen sulfide (H2S) treatment, the by-product waste is acid from the digested H2S. This lowers the pH and requires the use of caustic to buffer the water and nutrient solution that is recirculated within the scrubber to maintain a neutral pH. The captured gas containing contaminants enters the bottom of a vertical biological scrubber. Similar to how the gas enters any other type of chemical scrubber or single or dual pass odor control scrubber.

The gas stream travels upward. Passes over a media bed that has been cultured to grow live microorganisms. A biological odor control scrubber already has “artificial intelligence” because of the millions of microbes colonies it supports.

Read More

Topics:

water treatment issues,

odor control,

advanced treatment solutions,

biological scrubber,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

dissolved gases,

wastewater,

carbon dioxide,

degasifier,

gases,

RO system,

H2S Degasifier,

what is a scrubber

Odor control and acid scrubbers are both popular in many industries.

Read More

Topics:

odor control,

water treatment,

biological scrubber,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

dissolved gases,

carbon dioxide,

degasifier,

gases,

H2S Degasifier

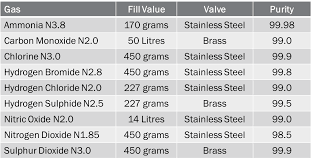

The type of Odor Control Wet Scrubber selected for the treatment and neutralization of Ammonia (NH3) gases depends on several variables, including the type and source of the ammonia gas and whether or not it is “Free” ammonia and or unionized.

Ammonia is a very miscible and stable molecule with solid hydrogen bonds, making it very soluble in water and difficult to treat without using a properly designed and sized ammonia scrubber. The concentrations, air flow rates, temperature of the gas stream, and chemical reagents being utilized, such as caustic to remove and then treat the ammonia, all play a significant role in the removal efficiency of the ammonia gas scrubber system. Unlike other types of “odor control scrubbers,” an ammonia scrubber is much more sensitive to variables such as the gas stream temperature because of the solubility of ammonia.

Ammonia is produced from nitrogen and hydrogen

the process is called the Haber Process by combining nitrogen with air and adding pressure, you can make ammonia.

It takes about 200 atmospheres of pressure, and the process varies from refinery to refinery. Still, on average, you can only make approximately 15% of ammonia during each pass which takes multiple passes to achieve the 15%. The reaction to make ammonia is exothermic when produced in a refining process.

However, ammonia is also formed in nature in smaller quantities. Most ammonia (90%) is utilized for fertilizer production, but ammonia can be found in food, pharmaceutical products, and cleaning supplies. When ammonia gas is released into the air, it has a very noxious and pungent odor that can be dangerous to inhale, so often, odor control scrubbers are required to capture and treat the ammonia gas.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

Decarbonation,

dissolved gases,

wastewater,

degasifier,

gases,

H2S Degasifier,

Ammonia