Odor control in a manufacturing facility is essential.

It prevents potential health risks and discomfort caused by the spread of chemicals, vapors, and fumes. Additionally, excessive vapors can hinder the efficiency of exhaust and natural ventilation systems.

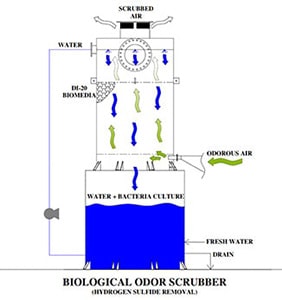

One effective solution for addressing odor issues is the installation of an Odor Control Scrubber Tower. These towers are part of the ventilation system in manufacturing plants and chemical processing facilities.

Odor control scrubbers help to remove noxious fumes and odors from exhaust and air streams. This is an effective way to improve air quality. This process involves utilizing an activated carbon filter and an ionic air filter

Key Considerations for Installing an Odor Control Scrubber Tower:

Health and Safety of Workers:

Industrial environments pose risks of exposure to hazardous fumes and gases for workers. Unhealthy odors emitted in high concentrations can jeopardize their well-being and safety. In some cases, these gases may even be combustible, adding an extra level of danger.

Odor control scrubber towers remove gases from the contaminated air, ensuring a safe working environment. These towers reduce the risk of health issues such as nausea, headaches, allergy symptoms, eye irritation, and loss of consciousness. This helps maintain worker productivity and prevents sickness caused by toxic fumes and gases.

Read More

Topics:

water treatment issues,

water quality,

odor control,

water treatment,

water distribution system,

advanced treatment solutions,

biological scrubber,

water plant,

safety,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

caustic,

Safe drinking water,

wastewater,

gases,

Biological Odor Control Scrubber,

Biological odor control,

what is a scrubber,

municipal water systems,

DeLoach Industries, Inc.,

Clean Water,

Industrial Odor Control

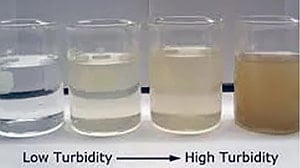

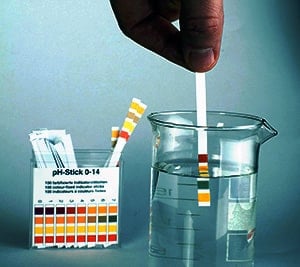

Water turbidity refers to how transparent or translucent the water is when examining or testing it for any use.

Water turbidity can impact food and beverage, municipal, industrial, and aquaculture operations. Turbidity is caused by suspended or dissolved particles in the water that scatter light which causes the water to appear cloudy or even murky.

Different particles can cause turbidity, including sediments such as silts and clay, fine inorganic or organic matter, algae or soluble colored organic compounds, and microscopic organisms. Turbidity is measured in a value referred to as NTU, which means Nephelometric Turbidity Unit. The EPA requires a turbidity level no higher than 0.3 NTU in the USA, and if a member of the partnership of safe drinking water, then the level must not exceed 0.1 NTU.

High turbidity can create habitats for other harmful elements, such as bacteria or metals, that can accumulate onto the particles. This increases the health risk for a potable water system. In aquaculture operations, increased turbidity from silts and sediments can harm and harm marine life, so it must be removed to safe levels. For the food and beverage industry, the impact of high turbidity can be both a safety concern and a visual and noticeable quality concern because if the turbidity is high, it can alter the physical look of the final product, for example, a distillery.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

water distribution system,

advanced treatment solutions,

water plant,

Safe drinking water,

De-Aeration,

decarbonator,

Aqua Farming,

Fish Farming,

Aquaculture,

Pisciculture,

Deagasification,

particulate matter,

filters,

Sand filters,

municipal water systems,

industrial facilities,

DeLoach Industries, Inc.,

turbidity

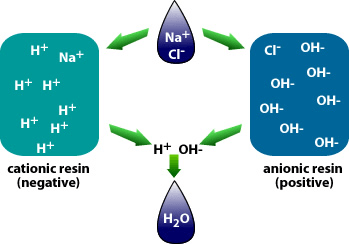

Water demineralization is also called deionization and is a process known as “Ion Exchange.”

In simple terms, water demineralization is “Water Purification.” The process involves removing dissolved ionic mineral solids from a feed-water process, typically for “Industrial” water applications. Still, it can also be utilized to remove dissolved solids from a water process for “Aquaculture,” “Food and Beverage,” and the “Municipal” markets.

Why is demineralization utilized? It can remove dissolved solids to near distilled water quality at a much lower capital and operational cost than other treatment processes such as membrane softening (Reverse Osmosis). Demineralization applies the science known as “Ion Exchange,” which attracts negative and positive charged ions and allows either to attach themselves to a negative ion depending on their respective current negative or positive charge during what is known as a resin cycle. In other technical articles, we will explore and go into more specific details on the science of the ion exchange process. Water that has dissolved salts and minerals has ions, either negatively charged ions known as “Anions” or positively charged ions known as “Cations.” To treat the water and remove these contaminants, the ions in the water are attracted to counter-ions, which have a negative charge. In a demineralization treatment process, there are pressure vessels that hold resin beads which are typically made of plastic. The beads are made from a plastic material with an ionic functional group that allows them to hold and maintain an electrostatic electrical charge. Some of these resin groups are negatively charged, referred to as “Anion” resins, while others hold a positive charge and are called “Cations” resins.

There are different applications to apply Ion exchange technologies, which is why you will often hear different terminology interchanged like deionization and demineralization. The raw water quality and the specific application will dictate the type of ion exchange process needed. For example, if the water contains a high level of hardness, the water will most likely contain Ca2+ or Mg2+ dissolved solids possessing a positive charge. To replace these hard ions, it is typical to utilize a resin bed with a salt ion like Na+. As the water passes over the resin bead material within the pressure vessel. The hard ions are replaced with the salt ion; therefore, all the hardness within the water is removed. However, the water will now contain a higher concentration of sodium ions, and this must be considered during the evaluation and selection process of the type of resin material to utilize for the specific application. If the water application requires high purity and the removal of as many solids as possible, then the term or process selected is referred to as demineralization.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

water distribution system,

advanced treatment solutions,

water plant,

hydrogen sulfide (H2S),

media packing,

Decarbonation,

ION Exchange Resin,

decarbonator,

degasifier,

RO system,

H2S Degasifier,

Aquaculture,

degassed water,

Co2 ph,

removal of CO2 from water,

Deagasification,

decarbonation of water,

hydrogen ion,

particulate matter,

municipal water systems,

industrial facilities,

automated control systems,

Ion exchange,

cations,

anions

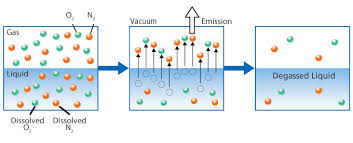

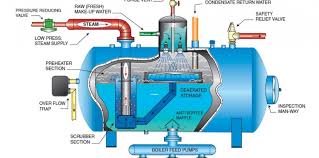

In the production and purification of water for industry

there are many types of different processes available to remove harmful minerals and gases from the water stream but the most effective process and most cost-effective from both a capital investment and operational cost is a “Forced Draft Degasification System” (Degasifier).

Degasification is used in a wide range of water processes for industrial and municipal applications which extend from the production of chemicals to the production of semiconductors and in all applications the need to remove contaminants from the water and dissolved gases is key to achieving the end results needed in the industrial water process. Water from the ground often contains elements such as calcium carbonate, manganese, iron, salts, hydrogen sulfide, and sulfur just to name a few of the basic contaminants and these naturally occurring elements can cause serious damage and consequences to process equipment such as boiler systems, piping, membranes, and cation and anion exchange resins used in the demineralization process.

Calcium carbonate can dissolve in water under certain pH ranges forming carbonic acid and releasing carbon dioxide (CO2) gases. These gases are not only very corrosive to equipment like boiler feed systems and boiler tubes but also attack the actual resin beds found in cation and anion softening and demineralization system causing an increase in regeneration and chemical consumption and resin bed replacement.

By incorporating a Force Draft Degasification system you can remove dissolved gasses

like CO2 and hydrogen sulfide (H2S) to as low as 99.999% and improve the cation and anion system performance, extend the resin bed life, and lower the operating cost of the water treatment process.

Quite often Forced Draft Degasification is utilized “post” treatment to also remove newly formed dissolved gases prior to entering the boiler feed system to prevent corrosion damage within the tubes and feed system and pumps. These gases are easily removed with the forced draft degasifier at a much lower cost than chemical additives or liquid cell degasification that requires higher capital cost and much higher operating cost.

Read More

Topics:

water treatment issues,

degasification,

pH levels of water,

iron oxidation,

water treatment,

water distribution system,

aluminum,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

calcium carbonate,

media packing,

pH levels,

Langilier index (LSI),

Decarbonation,

ION Exchange Resin,

dissolved gases,

feed water,

De-Aeration,

wastewater,

carbon dioxide,

decarbonator,

degasifier,

carbonic acid,

H2S Degasifier

Would it be possible for our odor control scrubbers to communicate with us and tell us when there are problems?

Or when they need service? With the new technological revolution, we are now this is quickly becoming a reality. DeLoach Industries is rapidly changing how water treatment and odor control and air emissions are treated with new advancements in artificial intelligence and integration into proven technologies.

Most operators will tell you that to keep and maintain an odor control system whether it's Biological Vs. chemical can be quite challenging depending on the type and source of the off-gas to be treated and depending on the type of chemical reagents being utilized such as acid or caustic solutions. When odor control systems such as a biological scrubber are met with varying flow rates, corrosive gases, or spiking concentrations an odor control system can be daunting to keep in balance and operating efficiency. But what if they could think or communicate with other devices or even operators for themselves? What if they could make corrections in caustic feed rates because of ammonia (NH3) concentration spikes, order chemicals like caustic or acid for pH control, and even inform us when they anticipate a problem for either the odor control scrubber or another critical component that it depends upon? That time has now arrived that’s to DeLoach Industries' new advancements to their equipment systems.

Read More

Topics:

degasification,

water distribution system,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

Decarbonation,

dissolved gases,

gases

In the United States manufacturing industry, an astonishing 400 million gallons of water per day (MGD) is consumed to generate steam.

Out of this amount, approximately 60 MGD is sent to blow-down drains, while another 300 MGD is used for direct injection of steam. The common denominator in all of these processes is the need for purified and treated water. Without proper treatment, manufacturers would face frequent shutdowns and increased capital expenditure, significantly impacting their cost of goods. One effective method of water treatment to protect boilers is through degasification and deaeration.

Degasification towers play a crucial role in removing harmful gases such as hydrogen sulfide (H2S), carbon dioxide (CO2), and often dissolved oxygen (DO). The elimination of these corrosive gases is vital for enhancing the lifespan and efficiency of boiler systems. If these gases are allowed to remain in the boiler feed water, particularly carbon dioxide (CO2), it can lead to disastrous consequences, including higher operating costs and reduced system longevity. Carbon dioxide (CO2) can convert into carbonic acid, creating a corrosive environment for the boiler and other critical components. In cases where an ion exchange process is implemented prior to the boiler, the presence of carbon dioxide (CO2) can drastically increase regeneration costs as the resins are consumed. By removing carbon dioxide (CO2), the life of the resin is extended, and the pH of the water is elevated, reducing the need for additional chemicals and further lowering operating costs.

Read More

Topics:

water treatment issues,

degasification,

iron oxidation,

water treatment,

water distribution system,

advanced treatment solutions,

water plant,

hydrogen sulfide (H2S),

Decarbonation,

ION Exchange Resin,

feed water,

De-Aeration,

steam generation,

steam generating boilers,

carbon dioxide,

steam,

decarbonator,

boiler system,

degasifier,

gases,

RO membrane,

carbonic acid,

RO system,

H2S Degasifier,

Boiler feed water

One of the largest consumers of energy in the US is water and wastewater treatment plants.

Because of the need for large horsepower pumps and blowers, a municipal water and wastewater treatment plant consumes a tremendous amount of kilowatt hours of electricity. The energy cost is factored into the “cost of production” of water or wastewater treatment, and the “rate base” charge is increased accordingly to the consumer.

Does Renewable Power Work in a Water Treatment Plant?

Because solar energy is “space intensive,” you do not see a lot of solar power being deployed across the USA at water treatment plants. In our opinion, this is a mistake, and most likely, the decision was made back when solar power output was much lower. With the increased efficiency of solar panels and decreased production cost, it makes tremendous sense to revisit the use of Solar energy to offset the operational cost of a water treatment plant or wastewater treatment plant operation.

Providing solar energy for specific pieces of process equipment is also a viable option when you consider deploying solar energy. For example, operating a Degasification tower or Decarbonator utilizing 10 350-watt solar panels will generate 3500 watts during peak daylight hours and enough to offset the cost of smaller horsepower blower motors. If the solar panels are configured as a canopy, they can also provide a nice shade or protective barrier above the piece of equipment if installed outdoors, as most packed column towers are located outside.

What about other forms of renewable energy? Do they work?

At water treatment or wastewater treatment facilities. Co-generation use has been around for many years at Wastewater plant facilities wastewater treatment plants. A cogeneration unit is a combination “Generator” to produce power and a “Thermal” energy source to produce heated water. The water can be used domestically or can be used to produce chilled water with the help of a Chiller system. The wastewater treatment plant provides a critical component by producing gases such as “Methane,” which can be used as a cogeneration unit fuel source. Water treatment plants do not produce methane or other combustible forms of gases like a cogeneration plant would produce, so you normally do not see Cogeneration system units deployed at a Water treatment facility.

Read More

Topics:

degasification,

water treatment,

water distribution system,

advanced treatment solutions,

water plant,

Decarbonation,

wastewater,

Recycling,

Global,

steam generation,

steam

A wide range of electric pumps, blowers, compressors, and material conveying equipment are used in water treatment facilities—whether municipal, industrial, aquaculture, or pisciculture. Despite their varied applications, they all share a common requirement: the need for an electric motor to deliver the torque and energy necessary to drive the equipment and fulfill its intended function.

One of the most common questions asked or considered during the design phase of the water treatment process is what type of motor enclosure should be selected. There are 7

types of motor enclosures that are available and defined by NEMA standards MG1-1.25 through MG 1.27. The final decision should be driven by the all of demands that the application will have placed upon it.

The selection of the type of motor enclosure can be a difficult choice.

If the application is for a process like Reverse Osmosis, Degasification, or Decarbonation, it is important to consider the efficiency of the motor and what the motor will be exposed to during its operating life cycle. We will briefly review each of the 7 different types that NEMA defines for motor enclosure types.

The ODP (open drip proof) is one of the most common types of enclosures.

The enclosure is open and vented at the back end of the motor and allows air to circulate in and around the motor windings carrying off heat. The ODP motor is designed to prevent liquid from entering the motor at a 15-degree angle based on the vertical alignment. ODP motors are normally utilized at water treatment facilities or aquaculture facilities where they will not be exposed to corrosive conditions such as HVAC systems.

Read More

Topics:

water treatment,

water distribution system,

advanced treatment solutions,

About DeLoach Industries,

water plant,

motors,

pumps,

municipal water systems

When operating a forced or induced draft water treatment tower system it is important to properly maintain your distribution system.

The distribution system is a fundamental component for any type of unit: an Aerator, Degasifier, Scrubber, or Air Stripper. It must be designed and constructed with precision and accuracy. This will ensure its optimal performance throughout its lifetime.

It is essential that the distribution system undergo regular and thorough maintenance. This will ensure it can do its job effectively.

Maintenance should include cleaning and inspecting pipes and connections. Additionally, worn or damaged parts should be replaced or repaired. Lastly, test the entire system to ensure proper functioning.

Regular maintenance is essential. It helps to prevent costly breakdowns or failures. Additionally, it minimizes disruptions to the distribution system.

Regular maintenance helps the distribution system run efficiently. This leads to better, more reliable service for customers.

The key role of the distribution system is to properly distribute the water flow over the media bed. If the distribution system is designed incorrectly then water will not be properly distributed which can cause multiple problems.

The distributor can be damaged or fouled. When this happens, the water pattern is changed. This affects the flow rate across the media bed. This can lead to low or high hydraulic flood conditions in the media bed.It is important to inspect the distribution system within 30 days of the initial startup of a system. Then decide, based upon application, if the future inspections can be extended to 90 or 180 days.

Iron oxidation and H2S require more frequent cleaning of the distribution system than a degasifier used for CO2 removal. This is because they are more corrosive.

Read More

Topics:

water treatment issues,

water treatment,

water distribution system,

Aerator