Understanding the Importance of Removing Dissolved Gases

Read More

Topics:

degasification,

hydrogen sulfide (H2S),

Decarbonation,

dissolved gases,

municipal water systems,

DeLoach Industries, Inc.,

Ion exchange,

Forced Draft Degasification,

induced draft degasifier,

water ph

Degasification and decarbonation are essential processes in water treatment that play a crucial role in improving water quality.

Read More

Topics:

degasification,

hydrogen sulfide (H2S),

Decarbonation,

dissolved gases,

decarbonator,

degasifier,

gases,

carbonic acid,

H2S Degasifier,

co2 dissolved in water,

degassed water,

decarbonation of water,

DeLoach Industries, Inc.,

hydrogen sulfide molar mass,

DeLoach Industries,

carbon filters,

removing hydrogen sulfide in water,

hydrogen sulfide gas,

dissolved oxygen

Requires an application commonly referred to as either “Degasification” or "Decarbonation" and it requires the use of a piece of water treatment equipment called either a “degasifier” or a “decarbonator”.

Both of these are similar in nature and are designed for Carbon Dioxide (CO2) removal from the incoming water. A properly designed decarbonator can remove 99.99% of the free carbon dioxide gas that is present in the water stream. One of the primary reasons for utilizing a decarbonator or degasifier for the removal of carbon dioxide gas is the raise the pH of the water without the need to add caustic. resulting in high-purity water.

The other reason is the remove the CO2 prior to treating the water with Ion Exchange which utilizes Anion or Cation resins to reduce the regeneration cycles for the resin beds. High concentrations of CO2 consume the ion charge within the resins and require more frequent regeneration cycles. The difference between anion and cation resins is that one is positively charged (anion) and the other is negatively charged (cation), cation resins, attract positive ions with their negative charge.

The term decarbonation describes the process of the removal of suspended gas or the conversion of carbonic acids into free Carbon Dioxide. Carbonic Acid (H2CO3) is stable at normal ambient anhydrous conditions. However, Carbonic Acid decomposes when not stable and in the presence of any water molecules to form carbon dioxide (CO2). The Carbonic acid breaks down when present in water and it is converted to a gas based upon certain conditions. It is common to have CO2 present in water requiring a decarbonation process when utilizing certain types of water filtration such as membrane filtration with reverse osmosis or it can be present when the need to adjust pH is required. When removing (CO2) the process is often referred to as “Decarbonation”, when removing (H2S) Hydrogen Sulfide the process is often referred to as “Degasification”.

Read More

Topics:

water treatment issues,

degasification,

pH levels of water,

aeration,

iron oxidation,

water treatment,

water plant,

bicarbonate,

hydrogen sulfide (H2S),

pH levels,

Decarbonation,

ION Exchange Resin,

dissolved gases,

De-Aeration,

wastewater,

carbon dioxide,

oxygen,

decarbonator,

degasifier,

gases,

carbonic acid,

H2S Degasifier

The Basics of Water Decarbonation

and the removal of carbon dioxide (CO2). The need to remove (CO2) is essential in most Aquaculture, Municipal, Industrial, and Food & Beverage Processes To understand you must familiarize yourself with Henry’s Law.

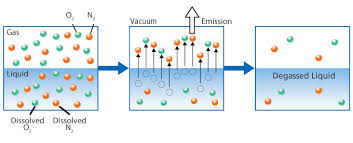

Henry's Law defines the method and proportional relationship between the amount of a gas in a solution in relation to the gas's partial pressure in the atmosphere. Often you will see and hear various terms like degasification, decarbonation, aeration, and even air stripping when discussing the removal of dissolved gases and other convertible elements from water. Understanding the impacts that Carbon Dioxide (CO2) can have on both equipment and aquatic life provides the basic reasons why the need to decarbonate water, exists. Carbon Dioxide (CO2) can exist naturally in the raw water supply or be the result of ph control and balance. In either case, the process called Decarbonation or Degasification provides the most cost-effective and efficient manner to reduce or tally remove (CO2) from the water. In addition to Carbon Dioxide (CO2), water can contain a variety of other contaminants that may impact the removal efficiency of the Carbon Dioxide. A variety of elements as well as dissolved gases such as oxygen, nitrogen, and carbon dioxide (CO2). A full analytical review of the water chemistry is required to properly design and size the “Water Treatment” process.

Breaking the bonds in water releases a dissolved gas

such as carbon dioxide (CO2) you must change the conditions of the vapor pressure surrounding the gas and allow the gas to be removed. There are many variables to consider when designing or calculating the “means and methods” of the removal of carbon dioxide (CO2). When I refer to the means and methods. I am referring to the design of a decarbonator and its components. The means equals the size and type (Hydraulic load) of the decarbonator and the “method” equals the additional variables such as the cubic foot of airflow (CFM) and “Ratio” of the air to water to accomplish the proportional condition needed to remove the carbon dioxide (CO2).

Read More

Topics:

water treatment issues,

degasification,

pH levels of water,

aeration,

iron oxidation,

water treatment,

water plant,

bicarbonate,

hydrogen sulfide (H2S),

pH levels,

Decarbonation,

ION Exchange Resin,

dissolved gases,

De-Aeration,

wastewater,

carbon dioxide,

oxygen,

degasifier,

gases,

carbonic acid,

H2S Degasifier,

removal of CO2 from water

The need for pH control with water degasification and decarbonation in water treatment includes almost every industry and includes;

The need for pH control with water degasification and decarbonation in water treatment includes almost every industry and including; Aquaculture, food, and beverage, industrial, municipal, and even pisciculture. In some water treatment applications, harmful gases such as Hydrogen Sulfide (H2S) are removed, while in other applications, Carbon Dioxide (CO2) or a combination of both. In addition, there's a host of other organic and inorganic elements found in water, both naturally occurring and manmade, that require removal during some part of the water treatment process.

In almost every application of degasification or decarbonation, you will hear or see the term pH used either by need or by the result. If, as an example, the water treatment application requires the removal of Hydrogen Sulfide (H2S) to be removed either as “free” gas or requires the conversion of Sulfides into (H2S) gas. You will often also see the need to adjust the pH of the water chemistry to maximize both the removal and the conversion to increase the efficiency of the equipment being utilized to remove the hydrogen sulfide, such as a degasification tower or commonly called a degasifier.

So, what is pH?

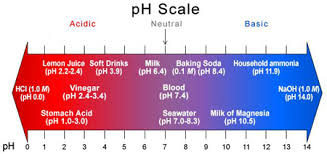

Water pH is a term used to describe whether or not the water is “acidic” or “basic.” pH ranges in water can be from 0-14. 0 is the most acidic, and 14 is at the far end and is the most basic, leaving “7” as the neutral state. A pH of 7 is neither acidic nor basic. So, what causes pH to be acidic? In nature, the most common cause of a low acidic pH in water is Carbon Dioxide (CO2) which occurs naturally when photosynthesis, decomposition, or respiration occurs in nature. The increase in CO2 causes an increase in ions, producing a lower pH in a simplified explanation.

How does pH play such a significant role in degasification and decarbonation?

As mentioned above in the example of the removal of certain harmful elements such as sulfides, sulfates, and free H2S hydrogen sulfide gases, to maximize the removal from water utilizing a degasification tower, it is essential to maintain as close to a pH of 5 as possible. When the pH rises above 5, the ability to convert and strip the free H2S gas from the water diminishes. When a degasification tower operates within this specific range and if it has been designed with the higher efficient distribution systems such as the ones utilized by DeLoach Industries, removal efficiencies of 99.999%- 100% can be achieved. If the pH rises to seven or above, the removal process becomes much more complex, and typically, you will have much lower results. The pH adjustment during the water treatment process is typically accomplished by adding commercially available acid, such as “sulphuric acid,” one of the most common in the municipal and food and beverage industry.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

Decarbonation,

dissolved gases,

carbon dioxide,

degasifier,

gases,

H2S Degasifier,

Aqua Farming,

Fish Farming,

Aquaculture

Hydrogen Sulfide Chemical Formula and the Molar Mass of H2S.

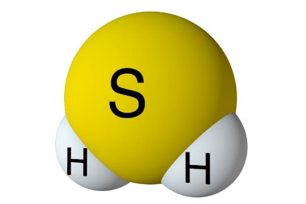

H2S is a naturally occurring chemical compound created in nature with the decay of organic material. Hydrogen sulfide is a chemical compound with a molecular formula comprised of (2) hydrogen atoms and (1) one sulfur atom. The formula is displayed as H2S. The gas is a colorless hydride, often known as the “Rotten egg gas.” This gas is very dangerous as it is poisonous and toxic to all life forms. It is also very corrosive and flammable. The H2S molar mass is 34.1 g/mol, with a melting point of -76 F (-60 C) and a melting point of –115.6F or (-82C).

Hydrogen sulfide gas is also created more often from a byproduct of a manufacturing process or the removal of water or wastewater treatment systems. In wastewater, as organic material decays, H2S is released, captured, and treated to protect human lives, reduce corrosion, H2S gas exposure, and H2S gas poisoning, H2S presence and reduce odor complaints. H2S gas is produced during manufacturing operations at refineries, pulp mills, and mining. These high levels of H2S are released during manufacturing. They must be captured and neutralized to protect human life from unwanted health effects such as pulmonary edemaand prevent excessive corrosion to your system. You cannot even smell gas at higher concentrations, and it is not distinguishable as “rotten egg gas,” which makes it even more dangerous and drives the need for hydrogen sulfide scrubbers equipment, fume scrubbers, or odor control scrubbers.

According to the “Agency for Toxic Substance & Disease Registry,” those who work within certain industries are exposed daily to higher levels of hydrogen sulfide gas than the normal public. Because the gas is also heavier than air, it will settle into lower places like manholes, tanks, and basements, and it will travel across the ground filling in low-level areas. To protect the public, OSHA (occupational safety and health administration) has set guidelines and rules known as “Permissible Exposure Limits” (PEL). A PEL is a legal limit a worker may be exposed to a chemical substance. The PEL limit for hydrogen sulfide is ten parts per million (10 ppm) over eight hours.

Read More

Topics:

water treatment issues,

degasification,

odor control,

water treatment,

advanced treatment solutions,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

dissolved gases,

wastewater,

decarbonator,

degasifier,

gases,

H2S Degasifier,

Hydrogen Sulfide Chemical Formula,

Molar mass,

Hydrogen Sulfide formula,

molar mass h2s,

hydrogen sulfide molar mass,

hydrogen sulfide gas

Basics of water decarbonation for dissolved organic carbon.

The water treatment industry continues to develop and evolve. Over the past two decades, there have been many new developments in technology and even more refinement in existing technologies such as "Degasification". The evolution and advancement of water treatment have been driven by the constantly increasing demand from an increase in population that demand cost-effective solutions and recognition to improve safety with the implementation of NSF 61 standards.

All human cultures on our planet share a single commonality: the dependency on water to survive.

Many existing technologies, such as "Degasification," have evolved with higher efficiency to meet the demand changes and provide safety to consumers and the systems. Degasification refers to the removal of dissolved gases from liquids, and the science to degasify water is based upon a chemistry equation known as "Henry's Law". The "proportionality factor" is called Henry's law constant" and was developed by William Henry in the early 19th century. Henry's Law states that "the amount of dissolved gas is proportional to its partial pressure in the gas." The most "cost" effective method to perform degasification is with the packed vertical tower called a "Degasifier” or “Decarbonator.”

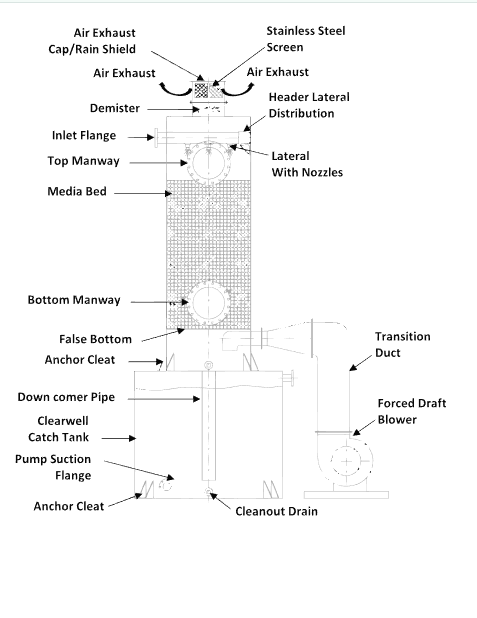

The key words in this previous sentence for owners, operators, and engineers to focus on is "the most cost-effective" as there is no other process more cost-effective at removing dissolved gases at the lowest cost than using a Degasifier or decarbonator. The process of degasification is simple enough to understand. Water is pumped to the top of a vertically constructed tower, where it first enters the tower through some type of distribution system at the same time, there is a cross-current air flowing up from the bottom by a blower located at the bottom of the tower, and the air encounters the water and is exhausted at the top of the tower through an exhaust port. There are various types of distribution systems, and we will explore these in later discussions. Once the water enters the top of the tower and passes through the distribution system, it then travels by gravity downward. The next thing the water encounters is some type of media packing. There are various forms of media packing offered in the degasification industry, and each type can offer higher performance or have the ability to deter fouling. The selection of the type, size, and volume is where the “experience, engineering, and understanding of each application” comes into play.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

water plant,

NSF/ANSI 61,

hydrogen sulfide (H2S),

media packing,

pH levels,

scaling,

caustic,

Decarbonation,

Safe drinking water,

dissolved gases,

carbon dioxide,

decarbonator,

boiler system,

degasifier,

carbonic acid,

H2S Degasifier,

Dissolved organic Carbon,

co2 dissolved in water

In the production and purification of water for industry

there are many types of different processes available to remove harmful minerals and gases from the water stream but the most effective process and most cost-effective from both a capital investment and operational cost is a “Forced Draft Degasification System” (Degasifier).

Degasification is used in a wide range of water processes for industrial and municipal applications which extend from the production of chemicals to the production of semiconductors and in all applications the need to remove contaminants from the water and dissolved gases is key to achieving the end results needed in the industrial water process. Water from the ground often contains elements such as calcium carbonate, manganese, iron, salts, hydrogen sulfide, and sulfur just to name a few of the basic contaminants and these naturally occurring elements can cause serious damage and consequences to process equipment such as boiler systems, piping, membranes, and cation and anion exchange resins used in the demineralization process.

Calcium carbonate can dissolve in water under certain pH ranges forming carbonic acid and releasing carbon dioxide (CO2) gases. These gases are not only very corrosive to equipment like boiler feed systems and boiler tubes but also attack the actual resin beds found in cation and anion softening and demineralization system causing an increase in regeneration and chemical consumption and resin bed replacement.

By incorporating a Force Draft Degasification system you can remove dissolved gasses

like CO2 and hydrogen sulfide (H2S) to as low as 99.999% and improve the cation and anion system performance, extend the resin bed life, and lower the operating cost of the water treatment process.

Quite often Forced Draft Degasification is utilized “post” treatment to also remove newly formed dissolved gases prior to entering the boiler feed system to prevent corrosion damage within the tubes and feed system and pumps. These gases are easily removed with the forced draft degasifier at a much lower cost than chemical additives or liquid cell degasification that requires higher capital cost and much higher operating cost.

Read More

Topics:

water treatment issues,

degasification,

pH levels of water,

iron oxidation,

water treatment,

water distribution system,

aluminum,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

calcium carbonate,

media packing,

pH levels,

Langilier index (LSI),

Decarbonation,

ION Exchange Resin,

dissolved gases,

feed water,

De-Aeration,

wastewater,

carbon dioxide,

decarbonator,

degasifier,

carbonic acid,

H2S Degasifier

Treating Hydrogen Sulfide for Environmental Safety

Read More

Topics:

odor control,

aeration,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

Decarbonation,

dissolved gases,

wastewater,

carbon dioxide,

degasifier,

gases,

Amine,

H2S Degasifier

Would it be possible for our odor control scrubbers to communicate with us and tell us when there are problems?

Or when they need service? With the new technological revolution, we are now this is quickly becoming a reality. DeLoach Industries is rapidly changing how water treatment and odor control and air emissions are treated with new advancements in artificial intelligence and integration into proven technologies.

Most operators will tell you that to keep and maintain an odor control system whether it's Biological Vs. chemical can be quite challenging depending on the type and source of the off-gas to be treated and depending on the type of chemical reagents being utilized such as acid or caustic solutions. When odor control systems such as a biological scrubber are met with varying flow rates, corrosive gases, or spiking concentrations an odor control system can be daunting to keep in balance and operating efficiency. But what if they could think or communicate with other devices or even operators for themselves? What if they could make corrections in caustic feed rates because of ammonia (NH3) concentration spikes, order chemicals like caustic or acid for pH control, and even inform us when they anticipate a problem for either the odor control scrubber or another critical component that it depends upon? That time has now arrived that’s to DeLoach Industries' new advancements to their equipment systems.

Read More

Topics:

degasification,

water distribution system,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

Decarbonation,

dissolved gases,

gases