If you’ve been reading the news lately, you know nanoparticles are not so great. In everything from cosmetics to water filters, nanoparticles have been shown to cause various health problems. But what exactly are nanoparticles, and how can you protect yourself from their harmful effects? Let’s answer these questions and more with this quick guide on removing nanoparticles from your drinking water.

Read More

Topics:

water treatment issues,

water quality,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

water plant,

safety,

Safe drinking water,

Global,

distillation,

RO membrane,

RO system,

particulate matter,

filters,

municipal water systems,

residential well water systems,

DeLoach Industries, Inc.,

Drinking Water,

Clean Water,

Water Test,

Water Test Kit,

DeLoach Industries,

technology,

minerals,

temperature,

nanoparticles,

Cosmetics,

Nano,

make-up,

organ function,

contaminants,

pressure filters,

reverse osmosis,

carbon filters,

UV filters,

activated carbon

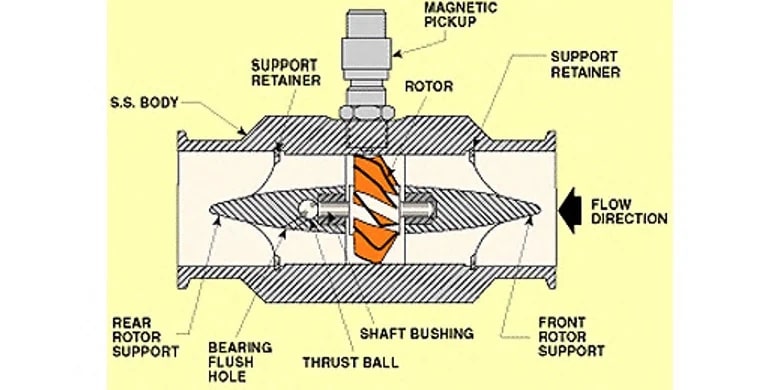

In water treatment systems it is often important to measure the rate at which water is flowing through the system. Data from flow measurement devices can be used to control chemical dosing, set pump speeds, control filter loading rates, inform maintenance programs, and other tasks necessary for the operation of a water treatment facility or on key components such as Degasification and Decarbonation systems or Biological Odor Control Systems. As with most types of instrumentation, there is an array of technologies that can be used for the task, each one with various strengths and optimal applications. For modern electronically controlled systems, the most common types of flow sensors used are axial turbine flowmeters, paddlewheel flowmeters, differential pressure/orifice plate flow transducers, and magnetic flowmeters. This article will briefly discuss the technology and features of each of these types.

A turbine flow meter,

consists of a tube that contains supports to hold a multi-bladed metal turbine in the center. The turbine is designed to have close clearance to the walls of the tubing such that nearly all of the water is made to flow through the turbine blades as it travels through the pipe. The turbine is supported on finely finished bearings so that the turbine will spin freely even under very low flows. As the turbine spins, a magnetic pickup located outside of the flowmeter housing is used to sense the tips of the turbine blade spinning past the pickup. An amplifier/transmitter is then used to amplify the pulses and either transmit them directly or convert the pulse frequency into an analog signal that is then sent to a programmable controller for further use elsewhere in the system. One advantage of a turbine flowmeter is that the electronics are separated from the fluid path. The magnetic pickup is the only electronic component, and it is installed outside of the turbine housing, reading the presence of the turbine blade tips through the wall of the sensor body. In clean water applications, this can be advantageous because the magnetic pickup can be replaced if needed without removing the turbine from service. However, the turbine itself covers most of the pipe area and creates back pressure in the system, requiring increased pumping energy to move a given amount of water. In Industrial Water Treatment or Filtration Treatment, turbines can also easily become fouled or jammed if they are used to measure water or other fluids with entrained solids, algae or bacteria cultures which cause significant accumulation, or corrosive chemical components that can degrade the turbine bearings.

Read More

Topics:

water quality,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

water plant,

pumps,

Alkalinity,

Safe drinking water,

wastewater,

Recycling,

pharmaceutical water,

Aqua Farming,

Aquaculture,

Pipe Size,

municipal water systems,

industrial facilities,

DeLoach Industries, Inc.,

actuated valves,

pump controls,

Drinking Water,

Clean Water,

Water Test,

Water Test Kit,

DeLoach Industries,

civil engineers

Basics of water decarbonation for dissolved organic carbon.

The water treatment industry continues to develop and evolve. Over the past two decades, there have been many new developments in technology and even more refinement in existing technologies such as "Degasification". The evolution and advancement of water treatment have been driven by the constantly increasing demand from an increase in population that demand cost-effective solutions and recognition to improve safety with the implementation of NSF 61 standards.

All human cultures on our planet share a single commonality: the dependency on water to survive.

Many existing technologies, such as "Degasification," have evolved with higher efficiency to meet the demand changes and provide safety to consumers and the systems. Degasification refers to the removal of dissolved gases from liquids, and the science to degasify water is based upon a chemistry equation known as "Henry's Law". The "proportionality factor" is called Henry's law constant" and was developed by William Henry in the early 19th century. Henry's Law states that "the amount of dissolved gas is proportional to its partial pressure in the gas." The most "cost" effective method to perform degasification is with the packed vertical tower called a "Degasifier” or “Decarbonator.”

The key words in this previous sentence for owners, operators, and engineers to focus on is "the most cost-effective" as there is no other process more cost-effective at removing dissolved gases at the lowest cost than using a Degasifier or decarbonator. The process of degasification is simple enough to understand. Water is pumped to the top of a vertically constructed tower, where it first enters the tower through some type of distribution system at the same time, there is a cross-current air flowing up from the bottom by a blower located at the bottom of the tower, and the air encounters the water and is exhausted at the top of the tower through an exhaust port. There are various types of distribution systems, and we will explore these in later discussions. Once the water enters the top of the tower and passes through the distribution system, it then travels by gravity downward. The next thing the water encounters is some type of media packing. There are various forms of media packing offered in the degasification industry, and each type can offer higher performance or have the ability to deter fouling. The selection of the type, size, and volume is where the “experience, engineering, and understanding of each application” comes into play.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

water plant,

NSF/ANSI 61,

hydrogen sulfide (H2S),

media packing,

pH levels,

scaling,

caustic,

Decarbonation,

Safe drinking water,

dissolved gases,

carbon dioxide,

decarbonator,

boiler system,

degasifier,

carbonic acid,

H2S Degasifier,

Dissolved organic Carbon,

co2 dissolved in water

A wide range of electric pumps, blowers, compressors, and material conveying equipment are used in water treatment facilities—whether municipal, industrial, aquaculture, or pisciculture. Despite their varied applications, they all share a common requirement: the need for an electric motor to deliver the torque and energy necessary to drive the equipment and fulfill its intended function.

One of the most common questions asked or considered during the design phase of the water treatment process is what type of motor enclosure should be selected. There are 7

types of motor enclosures that are available and defined by NEMA standards MG1-1.25 through MG 1.27. The final decision should be driven by the all of demands that the application will have placed upon it.

The selection of the type of motor enclosure can be a difficult choice.

If the application is for a process like Reverse Osmosis, Degasification, or Decarbonation, it is important to consider the efficiency of the motor and what the motor will be exposed to during its operating life cycle. We will briefly review each of the 7 different types that NEMA defines for motor enclosure types.

The ODP (open drip proof) is one of the most common types of enclosures.

The enclosure is open and vented at the back end of the motor and allows air to circulate in and around the motor windings carrying off heat. The ODP motor is designed to prevent liquid from entering the motor at a 15-degree angle based on the vertical alignment. ODP motors are normally utilized at water treatment facilities or aquaculture facilities where they will not be exposed to corrosive conditions such as HVAC systems.

Read More

Topics:

water treatment,

water distribution system,

advanced treatment solutions,

About DeLoach Industries,

water plant,

motors,

pumps,

municipal water systems

Following NSF/ANSI 61 regulations when designing and selecting the materials for the manufacturing of water treatment equipment.

It is important to understand what regulatory standards or constructions standard may be required to be compliant. This includes the designing and fabrication of systems such as reverse osmosis utilizing membrane technology, decarbonation of Carbon Dioxide, degasification of Hydrogen Sulfide, and water filtration for the removal of micron particles from potable and nonpotable water processes.

One requirement that engineers and manufacturers often encounter is called NSF /ANSI 61. NSF is an international and nonprofit, nongovernmental organization that is focused and dedicated to public health and safety as it relates to potable water systems and their components. NSF/ANSI 61 developed and established minimum requirements for the control of potential adverse human health effects from products and their components that contact with drinking water.

DeLoach Industries Inc. manufactures multiple types of water treatment equipment and adheres to strict compliance with NSF/ANSI 61 standards with all of their manufacturing procedures and practices. This strict adherence assures owners that water treatment equipment like decarbonation and degasification towers, reverse osmosis, and ion exchange that the equipment and material are all in full compliance with the NSF/ANSI 61 requirements.

Read More

Topics:

water quality,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

fabrication,

contact molded process,

hydrogen sulfide (H2S),

Decarbonation,

wastewater,

carbon dioxide,

decarbonator,

H2S Degasifier,

ansi61,

nsf/ansi61

Read More

Topics:

water treatment issues,

water quality,

pH levels of water,

aeration,

water treatment,

advanced treatment solutions,

fiberglass,

About DeLoach Industries,

fabrication,

biological scrubber,

Chemical Odor,

media packing,

pH levels,

Decarbonation,

De-Aeration,

decarbonator,

boiler system,

distillation,

degasifier,

RO system,

H2S Degasifier,

Fish Farming,

Aquaculture,

Pisciculture,

Biological Odor Control Scrubber,

Biological odor control,

removal of CO2 from water,

Deagasification,

decarbonation of water,

Sand filters,

Filter Media,

municipal water systems,

greensand,

DeLoach Industries, Inc.,

Drinking Water