If you’ve been following the news, you know a growing problem with PFAS (per- and poly-fluoroalkyl substances) exists.

PFAS, a group of synthetic chemicals in a wide range of products, is causing a growing concern. Despite their widespread use, some PFAS compounds have been found to degrade into potentially harmful byproducts like PFAS-methyl tetrahydrofuran. What's more alarming is that these chemicals have infiltrated our drinking water sources, even in areas with high water tables. This is why it's crucial to understand effective methods for removing PFAS from water. What should you do if you suspect that there’s a problem with your water? Check the source of the water, test it, and treat it if necessary.

Follow these steps to remove PFAS from drinking water.

Test Your Water

Although knowing how to remove contaminants is essential, it’s even more important to understand how to test your water for contamination. A water test kit can help you determine whether there are contaminants in your water and whether they are at a dangerous level. You can purchase water test kits at grocery stores, hardware stores, and online retailers. Generally, these kits come with the standard set of tests for a home water filtration system, but they also often include tests for specific contaminants. Use these tests to determine whether your water is safe to drink. If your water contains contaminants, remove them from your water source. This can be done by digging a more bottomless well, installing a water filtration system, or getting a water purification system. If your water does not contain contaminants, you don’t need to do anything except continue drinking your water.

Check the Source

Understanding the source of your water is a crucial step in addressing contamination. Whether you have a well or a water treatment system, knowing where your water comes from can provide valuable insights. By tracing the water's journey from the source, you can determine if contamination occurs upstream. This knowledge is essential for well owners, who might overlook the significance of understanding their water source. If you find contamination at the source, you can address it immediately, such as reducing the distance between the source and your dwelling or seeking alternative, uncontaminated sources.

Read More

Topics:

water treatment issues,

water quality,

odor control,

water treatment,

advanced treatment solutions,

Chemical Odor,

Safe drinking water,

RO system,

filters,

Filter Media,

residential well water systems,

DeLoach Industries, Inc.,

backwash,

Carbon Filter,

Micron Filter,

Drinking Water,

Clean Water,

Contaminated Water,

Water Source,

Sediment Filter,

PFA's,

Water Test,

Water Test Kit

PFOA and PFOS are man-made chemicals used in various products to simplify life.

Forever chemicals, also known as synthetic chemicals called PFAS, have gained recognition. Scientists created these chemicals to make products resistant to water, stains, and sticking. The United States initially utilized them in the 1950s.

DuPont introduced Teflon in the 1950s to help Americans have nonstick cookware and make their lives easier. Americans and people from other countries liked this new improvement and soon used these substances in many different products.

These chemicals are resistant to water and lipids, so they don't break down and last a long time in the environment.

Over time, companies have used these chemicals in manufacturing various products, such as firefighting foam, food packaging, and cosmetics. As a result, these chemicals have entered the air, water, soil, and food production. They discontinued the use of PFAS and their other compounds in the mid-1970s.

People believe that contamination has affected more than 7000 metric tons of Fluorochemicals. PFOAs and PFOS, which can cause various health problems, have exposed many Americans and people in the USA.

PFOA chemicals contaminated 1% of public drinking water supply systems in 2016. The EPA did not regulate safe levels of PFOA and PFOS in drinking water systems for many years.

Read More

Topics:

water quality,

advanced treatment solutions,

pH levels,

Safe drinking water,

RO system,

particulate matter,

Filter Media,

municipal water systems,

DeLoach Industries, Inc.,

Drinking Water,

Clean Water,

PFA's,

DeLoach Industries,

nylon,

Cosmetics,

reverse osmosis,

water process system,

removing PFAS & PFOS,

pfas exposure,

health effects of pfas,

exposure to pfas,

nonstick cookware,

food packaging,

water treatment standards,

PFOS,

safe drinking water act,

pfoa regulations,

the environmental protection agency,

drinking water standards,

water resistant clothing,

environmental safety,

forever chemicals

PFAS, or 'the forever chemicals, due to their long-lasting nature, are present in nonstick cookware, food packaging, and stain repellents and can cause health issues. Knowing the sources, making conscious decisions about products, limiting processed and packaged foods, and opting for safer alternatives are essential. You can protect yourself and your family from potential harm through these steps.

What is PFAS?

PFAS are a class of chemical substances used in various commercial and industrial applications, including nonstick cookware, stain repellents, and food packaging.

There are two main types of PFAS:

- Traditional PFAS

- Next-generation PFAS (also known as 'long-chain' PFAS).

Traditional PFAS include perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS), which have been phased out in the United States due to health concerns.

Next-generation PFAS such as perfluorohexane sulfonic acid (PFHxS), perfluoroheptanoic acid (PFHpA), and perfluorononanoic acid (PFNA) have also been identified as contaminants in drinking water and other consumer products. Unfortunately, next-generation PFAS are not regulated by the United States Environmental Protection Agency (EPA).

Health effects of PFAS

PFAS exposure at low levels can cause a few health risks and medical conditions, such as weakened immunity, thyroid issues, and cancer. Research is ongoing to see if it can impact fetus/baby growth and development, but these results are not definitive. Pregnant women can pass on PFAS to their fetuses, which could hurt the infant's health. Also, children exposed to PFAS in their young years may be at a higher risk for getting ADHD in the future.

Read More

Topics:

water quality,

advanced treatment solutions,

Safe drinking water,

Global,

distillation,

DeLoach Industries, Inc.,

Drinking Water,

Clean Water,

Contaminated Water,

PFA's,

Water Test,

Water Test Kit,

DeLoach Industries,

make-up,

removing PFAS & PFOS,

pfas exposure,

health effects of pfas,

exposure to pfas,

nonstick cookware,

food packaging

If you’ve been reading the news lately, you know nanoparticles are not so great. In everything from cosmetics to water filters, nanoparticles have been shown to cause various health problems. But what exactly are nanoparticles, and how can you protect yourself from their harmful effects? Let’s answer these questions and more with this quick guide on removing nanoparticles from your drinking water.

Read More

Topics:

water treatment issues,

water quality,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

water plant,

safety,

Safe drinking water,

Global,

distillation,

RO membrane,

RO system,

particulate matter,

filters,

municipal water systems,

residential well water systems,

DeLoach Industries, Inc.,

Drinking Water,

Clean Water,

Water Test,

Water Test Kit,

DeLoach Industries,

technology,

minerals,

temperature,

nanoparticles,

Cosmetics,

Nano,

make-up,

organ function,

contaminants,

pressure filters,

reverse osmosis,

carbon filters,

UV filters,

activated carbon

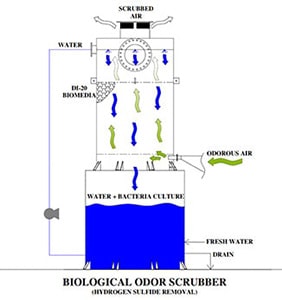

Odor control in a manufacturing facility is essential.

It prevents potential health risks and discomfort caused by the spread of chemicals, vapors, and fumes. Additionally, excessive vapors can hinder the efficiency of exhaust and natural ventilation systems.

One effective solution for addressing odor issues is the installation of an Odor Control Scrubber Tower. These towers are part of the ventilation system in manufacturing plants and chemical processing facilities.

Odor control scrubbers help to remove noxious fumes and odors from exhaust and air streams. This is an effective way to improve air quality. This process involves utilizing an activated carbon filter and an ionic air filter

Key Considerations for Installing an Odor Control Scrubber Tower:

Health and Safety of Workers:

Industrial environments pose risks of exposure to hazardous fumes and gases for workers. Unhealthy odors emitted in high concentrations can jeopardize their well-being and safety. In some cases, these gases may even be combustible, adding an extra level of danger.

Odor control scrubber towers remove gases from the contaminated air, ensuring a safe working environment. These towers reduce the risk of health issues such as nausea, headaches, allergy symptoms, eye irritation, and loss of consciousness. This helps maintain worker productivity and prevents sickness caused by toxic fumes and gases.

Read More

Topics:

water treatment issues,

water quality,

odor control,

water treatment,

water distribution system,

advanced treatment solutions,

biological scrubber,

water plant,

safety,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

caustic,

Safe drinking water,

wastewater,

gases,

Biological Odor Control Scrubber,

Biological odor control,

what is a scrubber,

municipal water systems,

DeLoach Industries, Inc.,

Clean Water,

Industrial Odor Control

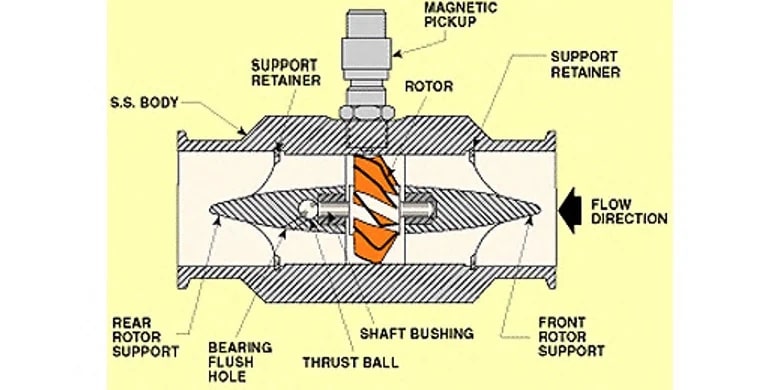

In water treatment systems it is often important to measure the rate at which water is flowing through the system. Data from flow measurement devices can be used to control chemical dosing, set pump speeds, control filter loading rates, inform maintenance programs, and other tasks necessary for the operation of a water treatment facility or on key components such as Degasification and Decarbonation systems or Biological Odor Control Systems. As with most types of instrumentation, there is an array of technologies that can be used for the task, each one with various strengths and optimal applications. For modern electronically controlled systems, the most common types of flow sensors used are axial turbine flowmeters, paddlewheel flowmeters, differential pressure/orifice plate flow transducers, and magnetic flowmeters. This article will briefly discuss the technology and features of each of these types.

A turbine flow meter,

consists of a tube that contains supports to hold a multi-bladed metal turbine in the center. The turbine is designed to have close clearance to the walls of the tubing such that nearly all of the water is made to flow through the turbine blades as it travels through the pipe. The turbine is supported on finely finished bearings so that the turbine will spin freely even under very low flows. As the turbine spins, a magnetic pickup located outside of the flowmeter housing is used to sense the tips of the turbine blade spinning past the pickup. An amplifier/transmitter is then used to amplify the pulses and either transmit them directly or convert the pulse frequency into an analog signal that is then sent to a programmable controller for further use elsewhere in the system. One advantage of a turbine flowmeter is that the electronics are separated from the fluid path. The magnetic pickup is the only electronic component, and it is installed outside of the turbine housing, reading the presence of the turbine blade tips through the wall of the sensor body. In clean water applications, this can be advantageous because the magnetic pickup can be replaced if needed without removing the turbine from service. However, the turbine itself covers most of the pipe area and creates back pressure in the system, requiring increased pumping energy to move a given amount of water. In Industrial Water Treatment or Filtration Treatment, turbines can also easily become fouled or jammed if they are used to measure water or other fluids with entrained solids, algae or bacteria cultures which cause significant accumulation, or corrosive chemical components that can degrade the turbine bearings.

Read More

Topics:

water quality,

water treatment,

advanced treatment solutions,

About DeLoach Industries,

water plant,

pumps,

Alkalinity,

Safe drinking water,

wastewater,

Recycling,

pharmaceutical water,

Aqua Farming,

Aquaculture,

Pipe Size,

municipal water systems,

industrial facilities,

DeLoach Industries, Inc.,

actuated valves,

pump controls,

Drinking Water,

Clean Water,

Water Test,

Water Test Kit,

DeLoach Industries,

civil engineers

Water treatment towers and storage tanks are high places that require special precautions when entering. While the majority of people who enter these locations for work can be trusted, there are some hazards that make it more important than usual to follow safety procedures.

These locations can get very hot and humid, and can also be filled with harmful chemicals and microorganisms that can cause serious health issues if inhaled or absorbed through the skin. Therefore, the general standard for workplace safety is much higher when entering locations like these.

Make sure you have read and understood the following information about safety when entering a water treatment plant. It will help you understand how to stay safe and protect yourself from harm when entering a water treatment plant. normal installation, maintenance, or even emergency repairs, it is often required to enter into a water treatment tower (degasifier, air stripper, decarbonator, or clear well/ storage tank). When this occurs, full safety protocols should be followed at all times, in accordance with OSHA regulations. A tower or tank B classification is a "Confined Space" location. For more information visit the OSHA confined space regulations page.

In addition, there are other safety risks that an operator or technician can be exposed to while inside these types of closed locations. The risk can come from fumes of hydrogen sulfide (H2S), chlorine from an injection line, or a lack of oxygen O2. A proper confined space permit should be prepared and only technicians with proper training and certifications should enter into these types of confined spaces.

Read More

Topics:

water treatment issues,

water quality,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

safety,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

media packing,

scaling,

caustic,

Safe drinking water,

dissolved gases,

wastewater,

carbon dioxide,

degasifier,

gases,

Ammonia,

what is a scrubber,

Hydrogen Sulfide formula,

Deagasification,

Filter Media,

DeLoach Industries, Inc.,

Drinking Water,

Clean Water,

Contaminated Water,

OSHA