In the United States manufacturing industry, an astonishing 400 million gallons of water per day (MGD) is consumed to generate steam.

Out of this amount, approximately 60 MGD is sent to blow-down drains, while another 300 MGD is used for direct injection of steam. The common denominator in all of these processes is the need for purified and treated water. Without proper treatment, manufacturers would face frequent shutdowns and increased capital expenditure, significantly impacting their cost of goods. One effective method of water treatment to protect boilers is through degasification and deaeration.

Degasification towers play a crucial role in removing harmful gases such as hydrogen sulfide (H2S), carbon dioxide (CO2), and often dissolved oxygen (DO). The elimination of these corrosive gases is vital for enhancing the lifespan and efficiency of boiler systems. If these gases are allowed to remain in the boiler feed water, particularly carbon dioxide (CO2), it can lead to disastrous consequences, including higher operating costs and reduced system longevity. Carbon dioxide (CO2) can convert into carbonic acid, creating a corrosive environment for the boiler and other critical components. In cases where an ion exchange process is implemented prior to the boiler, the presence of carbon dioxide (CO2) can drastically increase regeneration costs as the resins are consumed. By removing carbon dioxide (CO2), the life of the resin is extended, and the pH of the water is elevated, reducing the need for additional chemicals and further lowering operating costs.

Read More

Topics:

water treatment issues,

degasification,

iron oxidation,

water treatment,

water distribution system,

advanced treatment solutions,

water plant,

hydrogen sulfide (H2S),

Decarbonation,

ION Exchange Resin,

feed water,

De-Aeration,

steam generation,

steam generating boilers,

carbon dioxide,

steam,

decarbonator,

boiler system,

degasifier,

gases,

RO membrane,

carbonic acid,

RO system,

H2S Degasifier,

Boiler feed water

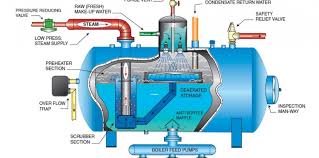

The operation of steam-generating boilers and the process of removing dissolved gases from the feed water is of utmost importance.

Deaeration is essential in the boiler system process.

Deaeration involves removing oxygen (O2) and carbon dioxide (CO2) from the water. Removing oxygen and carbon dioxide from the water before it enters the boiler system is essential. This prevents corrosion of the boiler system components and reduces costly maintenance and repairs to your system.

Oxygen and carbon dioxide can corrode and destroy metal components of the boiler system.

Corrosion can be costly to repair or replace. This is due to oxygen (O2) and carbon dioxide (CO2) not being removed from the water.

In order to avoid unwanted corrosion, it is necessary to treat the water before it enters the boiler system. This can be achieved through different techniques, including deaeration, chemical treatment, or mechanical filtration.

The deaeration process typically requires a deaerator. This device combines heat and vacuum to remove dissolved gases from water. The deaerator reduces the amount of dissolved solids in the water.This can improve the efficiency of the boiler system. Neglecting regular maintenance and inspection of the boiler can lead to severe corrosion damage and operational issues.

Read More

Topics:

Decarbonation,

dissolved gases,

feed water,

De-Aeration,

steam generating boilers,

carbon dioxide,

oxygen,

steam,

decarbonator,

boiler system