Avoid problems with calcium chlorite and corrosive gasses with your odor control scrubber.

When planning or designing an odor control system, one should pay close attention to several key variables that can cause havoc on a chemical odor control scrubber when trying to treat hydrogen sulfide or ammonia gases. The need for odor control occurs in many different forms. It is essential to understand the process that is creating the odorous or corrosive gas and the need for odor control & air emissions treatment.

First, begin to identify

all the potential obstacles that may creep up later after the chemical odor or corrosive gas control system goes online, like acid or caustic consumption. For example, chemical odor control systems designed for water treatment for the municipal industry are typically needed and attached to a degasification or decarbonation process, often needed to treat hydrogen sulfide (H2S). However, designers often may not pay close enough attention to the type of water process available for “make-up” water for the chemical scrubber. The addition of caustic can create scaling or fouling. This unknown variable of the makeup water quality can lead to a complete tower shutdown if the chemical scrubber distribution and media bed scales or fouls. The most commonly used chemicals for a hydrogen sulfide (H2S) scrubber are either chlorine in the form of sodium hypochlorite or caustic in the form of caustic soda. Both of these chemicals are common to a water treatment facility and are already in place to adjust and control pH.

The makeup water plays a significant role in the operation of a chemical scrubber.

When water containing high hardness levels is used as the source for the makeup water, your chemical scrubber can become fouled, and scaling can occur in a matter of hours, depending on the alkalinity and salts within the water. Solidification can occur from the scaling when combining sodium hypochlorite and raw feed water at specific pH ranges and these ranges are usually the range needed to achieve peak performance. Calcium chloride will form, and your chemical odor control scrubber will become a solid chunk of calcium chlorite making, making the ability for water or air to pass freely through the media packing next to impossible. No matter what type of media packing is utilized in the odor control or gas scrubber, it can foul and scale if the water chemistry is incorrect. Trust me when I say “been there and done that”! I have seen operators who have allowed a chemical scrubber to become out of balance with pH control and completely solidify the tower column to the degree that neither air nor water passage is possible. The problem can still occur with ammonia scrubbers but are different with different sets of parameters.

The best way to keep your chemical scrubber operating

at an optimum level, the makeup water is free from hardness (salts), and the alkalinity is corrected through pH adjustment with acid and caustic injection. I recommend using permeate water from a reverse osmosis system or adding a softener to condition the water before it enters the chemical scrubber. Next, always maintain your pH monitoring and feed control systems because if they become unreliable, your chemical scrubber can be headed to a certain disaster if the caustic, acid, or hypochlorite feed system fails. Of course, your removal efficiency will drop. Many times, operators will increase the chlorine feed system to the point where they only smell chlorine. Leaving the tower and assuming that the tower is operating effectively. But the reality is that the scrubber may only be treating 80% of the hydrogen sulfide (H2S) gas, and the chlorine smell is masking the balance. Some may ask why this is not a good practice to adopt. Soon with the new technology being deployed by DeLoach Industries, the different types of chemical scrubbers for off-gas and hydrogen sulfide treatment may be able to correct themselves with minimum operator interactions. DeLoach Industries is quickly adapting “artificial intelligence” (AI) into their line of chemical odor control, biological odor control, degasification, and decarbonation equipment systems. The answer is that the excess chlorine gas is not only expensive but also dangerous to humans and corrosive to all surrounding equipment. The equipment in and around a chemical scrubber will begin to corrode immediately. Electronics can fail quickly with the aggressive corrosion from the excess chlorine gas released when the scrubber is not operating optimally.

It is always best to operate the chemical scrubber

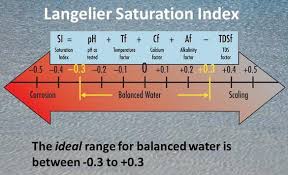

in the method, it was designed within the parameters recommended by the manufacturer. Make sure you monitor the makeup feed water and the pH of the recirculating water and add caustic or acid as needed. Keep a watchful eye on the water, and always check the Langelier Saturation Index number. Remember that being out of balance can create havoc in the chemical odor control treatment system. Adjustments to your caustic or acid feed system may be needed in hours or over a short time. When treating ammonia gases, the chemical reagents differ, but the need to control the pH remains the same. The addition of caustic is always needed when stripping ammonia from a water stream process, and the pH must remain high to remove the ammonia from the water and release it as a gas to treat in a scrubber. If the LSI number is too much in the positive, you will create the perfect situation for scaling. remember, the most common form of scaling in chlorine and caustic odor control system is calcium carbonate, and once fouled, it can be pretty difficult to reverse the process. Always check with the system manufacturer.

At DeLoach Industries, we receive calls from operators who have misplaced the O&M manual or just want to be sure who are rightfully looking for the correct operating parameters to keep the chemical scrubber performing at the design levels. We always provide immediate assistance to operators we know and recognize are trying to keep our systems and their water treatment plant running at top performance. If you need further assistance with an odor control scrubber, the professionals here at DeLoach Industries, Inc will be happy to assist you at (941) 371-4995.