Select the best type of odor control, fume, or air emission scrubber.

Industrial and municipal operations often face the challenges of capturing and treating air emissions from their process operations. Off-gases, fumes, and odor emissions can be generated from the downstream process or material handling, such as those in the municipal wastewater industry. However, industrial operations often generate fumes and off-gas air emissions from either the production of chemicals or the use and application of chemicals like acids and a wide range of other chemicals. These types of air emissions share a common need to be safely captured, contained, and treated to make the air steam safe before its release. Some types of air streams create an odor that becomes a nuisance, as is typical with municipal waste that often releases Hydrogen Sulfide (H2S) and or Mercaptans (R-SH) gas during decomposition.

Many variables should be considered

when beginning to choose the best type of air emission treatment process. Within the industry, there are wet chemical scrubbers, dry absorbent scrubbers, biological scrubbers, and destructive type scrubbers such as catalytic and thermal oxidizers and flare technology that utilize heat to destroy and consume and oxidize certain types of off-gases.

Each type of air emission process has its own parameters where it will perform optimally, and each type of scrubber has different levels of operating challenges and associated operating costs. So how does one select the best process for each application?

At DeLoach Industries, we like to help customers with this evaluation process by completing a checklist guide, which helps guide the customer to the most economical and safe solution. Going through this process can help eliminate costly mistakes that may otherwise be overlooked. Solutions are often selected by looking at the contamination only or by familiarity with the process.

Items that we consider during the selection process include;

- The type of contaminants and level of exposure risk

- The source of the emission

- The estimated flow rate

- The concentrations and fluctuations in gas stream loading

- The temperature of the gas or gases to treat

- By-product residual comparison with the destruction

- Particulate loading levels

- The type of facility and level of operators available

- Hours of operation

- The need for redundancy in the design

- Potential energy values of the gas

- Location of the treatment system to the source

All these variables and more need to be reviewed and considered when undertaking the design, engineering, and selection of the best odor control or air emission scrubber type to avoid costly mistakes in performance issues and, most importantly, operating costs. For example, specific chemical scrubbers require buffering or softening makeup water to avoid calcium carbonate scaling, and flares or oxidizers can destroy one contaminant while concentrating another, like hydrogen sulfide gas (H2S).

Sometimes, the ability to neutralize a gas or remove the odor is not the most crucial factor behind the technology selection. There are several different methods for treating air emissions and odor in industrial and municipal wastewater applications, and one needs to examine each type of process and its requirements to understand and evaluate the operating cost and performance reliability.

The most prevalent types of odor control and fume gas emission scrubbers on the market today are either “chemical” or “biological,” both types have been widely used for over three decades.

When choosing what type of odor control or fume scrubber is best for your application, you must first understand the parameters of the air waste stream

you must treat. It is always recommended to analyze the odor gases to understand the total loading rate and what type of chemicals are creating the odorous gases. You will often find methane and hydrogen sulfide combined with other organics, so understanding the chemical matrix of the gas is the first step in the selection process.

Biological Scrubber

The next step is to make sure you gather more than just one sample over a more significant time period. This is crucial in the selection of technology for odor control. If, after you collect your data, you see that you have concentrations that have wide variations over a day or even an hour with more than a 5% change, then a chemical scrubber may be your best choice. Biological scrubbers perform best when the concentrations remain steady and do not fluctuate. When concentrations change rapidly, biological growth cannot adjust fast enough. Therefore the scrubber will experience a “breakthrough” of untreated gases unless it is a two-stage scrubber with a carbon polishing unit.

Chemical Scrubber

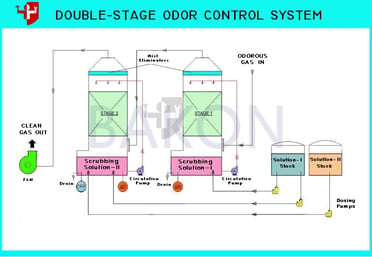

If the concentration levels fluctuate, are incredibly high, or have a wide variety of compounds in the gas mixture, then chemical scrubbers (single or dual pass) are often the best selection. The other two critical components of the selection process are the anticipated annual operating cost of the scrubber and what type of service the scrubber will receive. If the scrubber is located where there is not an active operator and it may be left at times unattended, this can drive the decision back towards selecting a biological scrubber that has fewer components that need maintaining. It is always best to gather as much information on the specific location and obtain good analytical data before making a final selection.

Some air emissions and odors come from the venting of tanks, while other odors are captured only after placing tank covers or hoods over the problem areas. If the odor stream is going to be pulled into the odor control scrubber, you typically will have a fresh air vent allowing makeup air to enter the tank. DeLoach Industries can help you evaluate your fume, gas, or odor problem, and our professionals can help guide you through the selection process. We interface directly with engineers when developing complex solutions and designs and provide full submitter support and design support services. DeLoach Industries can develop the most cost-effective, long-lasting solution for all your needs for air emissions, odor control, or your needs in Industrial Water Treatment. We work with our clients or their engineers to achieve the results needed, and all system solutions are backed with our full support and warranty. Celebrating now 60 years in business! For more information or to learn more, contact the professionals at DeLoach Industries Inc. at (941) 371-4995.