Do you think all distribution systems are made equal?

if you do you may be surprised that there is a lot of variation in manufacturing protocols for aerators, degasifiers, and decarbonators. Aerators are often found in use at Industrial Water Treatment and municipal water treatment facilities around the globe.

if you do you may be surprised that there is a lot of variation in manufacturing protocols for aerators, degasifiers, and decarbonators. Aerators are often found in use at Industrial Water Treatment and municipal water treatment facilities around the globe.

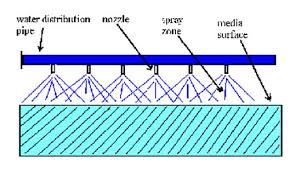

For water treatment, you may be surprised to learn that one of the key items that separate different types of aerators and decarbonators for water treatment is the type of distribution system it utilizes. To improve Carbon Dioxide (CO2) or Hydrogen Sulfide (H2S) removal you need to select the best distribution system for the tower and make sure it's maintained. Now, there are many types of aerators in general and the term is used broadly. From floating pond aerators to wastewater aerators, to vertical tower aerators, decarbonators, and degasifiers for industrial water treatment aerators. We will focus on vertical tower aerators for industrial water treatment. All types of Aerators and even degasifiers and even decarbonators and Odor Control Scrubbers require some type of distribution system to begin the process of gas transfer and to remove Hydrogen Sulfide (H2S) from water or Carbon Dioxide (CO2). It is important to evenly distribute the water or chemical solution across the media bed.

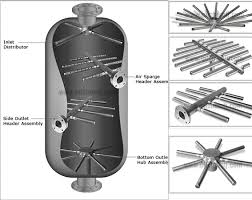

There are several types of distribution systems available and the three most common ones you will see on the marketplace are the “Tray” type, Weir, or the header lateral utilizing gas release “Nozzles”.

The selection of what type of distribution system is typically driven by the marketing side of who is selling you the tower. But in terms of real performance a distribution system utilizing a nozzle system will outperform a tray-type distributor. All packed towers are designed utilizing Henry’s Law Constant” theory of chemistry and what all towers rely upon is some type of method to break the surface tension of the water and expose the molecules of gases so that they either can escape or can be introduced to a reaction agent.

When towers are designed it is important to properly hydraulically load the top of the media bed. This is considered " Degasification Basics". This is important for many reasons and we will address these points in future updates. When using a properly designed nozzle distribution system such as a DeLoach Industries header lateral system then you get the benefit of both proper hydraulic load across the bed and you also gain anywhere from 4-10% removal efficiency depending upon the application. When looking at a chemical scrubber versus a biological scrubber you will notice they too have very different distribution systems. DeLoach Industries, Inc. has learned over its 60 years in business how to maximize gas transfer release. If designed and built properly the gas release process or interaction process (if designing a scrubber) has already begun “before” it enters the media bed.

So when designing the tower if the media bed is going to remove a certain percentage then you can be assured you will exceed that design slightly with a distribution system using a header lateral design with nozzles. The other interesting item about tray distribution systems is that they tend to allow more fouling and build-up to occur within the distributor simply because they have troughs or areas where solids can settle and be deposited. So if you want the highest performance and the least amount of maintenance then the Header Lateral Distributor with correct nozzle selection and design is the way to go. Remember, selecting a Decarbonation tower with the proper distribution system will save the life of your Ion Exchange resin bed and extend the period of regeneration. For more information or to learn more contact the professionals at DeLoach Industries Inc. at (941) 371-4995.