In process control systems, it is often required to handle fluids that have a harsh chemical nature. In these cases, it is necessary to be aware of material-chemical compatibility. Chemical compatibility is a general term referring to the way a specific chemical interacts with a specific material. This information is taken into consideration when selecting materials for construction for tanks, valves, pipework, tubing, and other devices that may encounter harsh chemicals. Common chemical types that are used in process systems are acids, bases, corrosives and oxidizers, and hydrocarbons. Typical chemical-resistant materials include natural and synthetic rubbers, vinyl polymers, fluoropolymers, and stainless steel. In order to determine which materials are compatible with certain chemicals, a chemical compatibility chart is often used. A chemical compatibility chart contains tabulated data about how a given material interacts with a given chemical.

Often, the manufacturer of the equipment or material in question will have their own compatibility chart for their specific goods. Most compatibility charts will have the same type of information. Materials will be categorized along one axis of the table, with fluids or gasses categorized along the other axis. At the intersection of a material with a fluid, you will find an indication of the level of compatibility. Some charts will use an A-F categorization, others may use a more graphical style. Most charts will be accompanied by a key or guide that explains how to use the table. There may also be multiple concentration levels and temperature ranges for a given fluid in cases where the distinction makes a difference with compatibility.

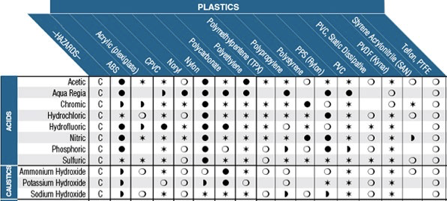

In the table excerpt below, you can see various plastics listed with common acids and bases. In this table, a dark circle represents severe effect, or no compatibility, a half circle represents minor effect, or general compatibility, and an empty circle represents no effect and excellent compatibility. A star represents compatibility at low temperatures and concentrations but deteriorating compatibility at higher temperatures or concentrations.

Figure 1: Compatibility Table Excerpt

As an example, let’s consider choosing tubing to carry a common water treatment chemical. The hypothetical system is a chemical injection system that uses 98% Sulfuric Acid to lower the pH of the water before it enters a degasification tower. Looking at the table in Figure 1, sulfuric acid is located on the bottom row of the acid group. Following the row across, you can see that there are multiple materials compatible with the acid at lower concentrations. The materials with the best resistance to sulfuric acid according to this table are Noryl, TPX, SAN, and Teflon/PTFE. Other materials such as PVC, CPVC, and PVDF are also good choices but would require more investigation with your specific concentration of acid to check applicability. Once narrowed down, referencing a material-specific chart can help add more context to the decision. For this example, let’s try to determine the best cost-effective choice for 98% sulfuric acid at ambient temperature (50F-75F). Under consideration are Teflon, PVC, and PVDF.

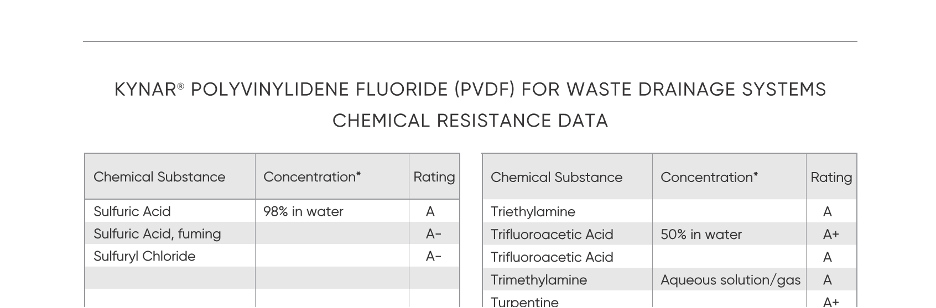

Figure 2: PVDF Compatibility

From the table excerpt in Figure 2, we see that PVDF has an A rating with 98% Sulfuric Acid. In the footnote, it says that an A rating means that it is suitable for continuous use in ambient conditions. This means that PVDF would be suitable for our application.

Next, let’s consider PVC:

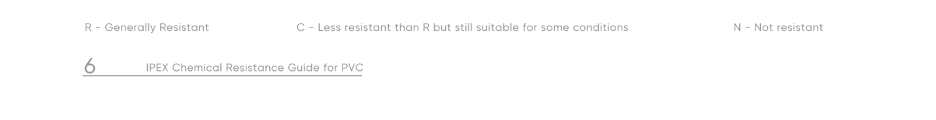

Figure 3: PVC Compatibility

Here, we see that PVC is rated “R” for “not resistant” to Sulfuric Acid above 94%.

Here, we see that PVC is rated “R” for “not resistant” to Sulfuric Acid above 94%.

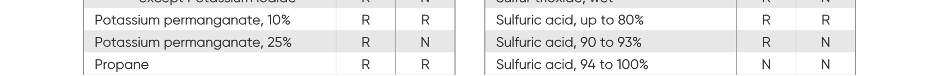

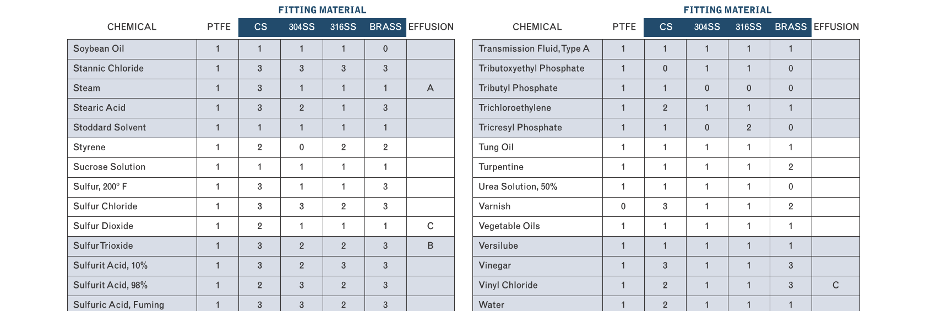

Finally, we will consider Teflon or PTFE. In Figure 4, we see that Teflon is rated “excellent” for all concentrations of Sulfuric Acid.

Figure 4: PTFE Compatibility

The final part of this exercise is to pick a material for the tubing. To recap, we are considering 98% Sulfuric Acid at ambient temperature. We initially considered PVC, Teflon, and PVDF based on a chemical compatibility summary table. We then went to more detailed tables that were tailored for specific materials, giving more specific information regarding the fluid conditions. From that information, we found that PVC is not compatible, Teflon is the most compatible and shows resistance even beyond the concentrations and temperatures we are considering, and PVDF shows good resistance at the planned concentration and temperature. This point is where the judgment call between budget and performance comes into play.

Teflon tubing and fittings are about twice as expensive as PVDF. In most water plant applications, PVDF would be the final choice because the system is built for a single purpose, and it can be expected that the chemical system would not be spontaneously exposed to either heated acid or acid with a concentration greater than 98%. The extra cost of using Teflon would not be justifiable for most water plants. However, in other applications such as laboratory chemical waste drains, PTFE would be the ideal choice since multiple concentrations or temperatures of acid could predictably be introduced to a chemical waste drain. As with most engineering decisions, there is almost never a single correct answer for a given application, and it ultimately comes down to a judgment call based on your conditions. With the methodology demonstrated here, you should be able to consider your next polymer pipework material selection from a more informed position. If you have more questions regarding the above information, please feel free to contact one of our professionals at DeLoach Industries, Inc.