When do you know if your decarbonation system needs service?

When a degasification tower or decarbonator becomes fouled, several indicators identify you may have a problem or that it's time to clean your system. If the efficiency of the degasifier has dropped, you will see an increased consumption rate of chemicals. If you remove less hydrogen sulfide gas from the degasifier, chlorine consumption will increase. When you increase the amount of chemical reaction occurring in the water, you will see an increase in the TSS levels and a drop in water quality. As the H2S reacts with chlorine, more solids will form and be present in the water, and the water quality will diminish.

Another indicator of a fouling condition is the pH adjustment in the Industrial Water Treatment industry. You are required to meet the set standards. As the performance of the tower drops, the removal of CO2 will also drop, leaving a higher pH level than may be desired. A quick inspection to check out the media bed should be performed. Also, do not forget to inspect the distribution system at the top of your tower and remember that all distribution systems are not alike, and inspecting the condition of each of them may require additional effort on your part. With a header lateral system, you need to inspect the distribution nozzles, but with a Weir or Tray type, you will need to check the amount of scale or fouling building up on the Weir edge or in the bottom of the pan. If the Weir edge becomes fouled unevenly, it will create "Channeling" of the water and increase the initial hydraulic load to a concentrated point on the media bed.

Using Carbon Dioxide removal (CO2) to increase your pH levels in water or prevent carbonic acid formation to protect and guard against corrosion and the media packing has become fouled, you will see an increased regeneration requirement on your ion exchange resin system. This is an indication that the decarbonation tower is not functioning properly.

Water Channeling can cause increased hydraulic loads

if the distribution system is fouled or plugged (as typical in weir systems), it will create what is known as a “channeling” effect inside of the tower. This causes an increase in hydraulic loading in one or more sections of the media bed and media surfaces. If this increases, too much hydraulic flooding will occur in those areas, and the unit will not properly perform. During a hydraulic flood, the degasifier or aerator media cannot obtain a proper air-to-water ratio loading rate, which decreases the equipment's efficiency.

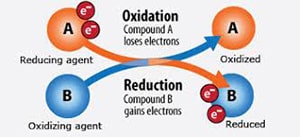

Oxidation of solids in the media can occur.

Oxidation of solids in the media can occur.

If solids or fouling is allowed to build and is not removed, structural damage can occur inside the degasification or aeration tower. If the media bed becomes fouled to the point where water flow is restricted, the weight on the internal structures of the tower will exceed the original design capability and cause the collapse of the media support plate and typically damage other internal components such as the air resistor or blower duct intake fittings or vents.

If your degasification or decarbonation tower system also includes a chemical or biological scrubber, please do not forget to inspect the internal condition of the scrubber during the maintenance inspection period. Excessive fouling in a scrubber will lower performance and can damage the internals, just like the water degasification tower. DeLoach Industries, Inc. offers a wide range of packed towers, scrubbers, and field support services for all your needs. For more information or to learn about carbon removal technologies, contact the professionals at DeLoach Industries Inc. at (941) 371-4995.