Ammonia (AM) is a common water pollutant that significantly impacts the water process industry.

It is not just polluting water bodies but also aqua wells and humidifiers. Generally, AM is produced from human sweat and urine and created from synthetic ammonia in industrial processes.

Ammonia has three types of amines – primary, secondary, and tertiary – all are toxic for humans and aquatic life.

- Primary Amine has two carbon and one nitrogen atom, also called methylamine or CHNH2.

- Secondary Amine has two nitrogen atoms with no carbon atom between them, also called Dimethylamine or CH2(NH)CH3.

- Tertiary Amine has three nitrogen atoms with no carbon atoms between them; thus, it’s called Trimethylamine or CH3C(NH)CH3.

In natural conditions, primary Amide bacteria produce Amide under high-temperature conditions. In an aqueous solution and soil environments with high pH levels (>6).

Primary amide can form by the dehydrogenation of nitriles, such as acetonitrile, which are further oxidized to form acetic acid.

Primary amide form by alkaline hydrolysis of nitro compounds such as 2-nitrophenol.

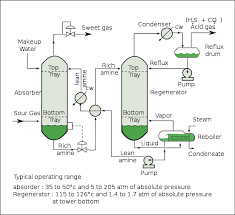

Process systems often need to recognize when the Degasification or Decarbonation system is failing or underperforming.

One critical signal used as verification is:

The consumption rate will increase in a process that also utilizes Amine in the downstream treatment, which can drastically increase operational costs in your distribution system.

A packed column tower begins to fail, and it can be associated with the following:

- Fouled media

- Failed distribution system

- Plugged intake vents

- Failing blower

The high-noise environment makes it difficult to hear the belt slipping or breaking. And could lead to other issues, such as poor-quality products and potential injury from water contamination or ammonia gas exposure.

One way to prevent this is by using an audible warning system. That alerts operators when there is a problem with the belt or blower motor. An indicator light that shows if there is a problem with the belt can be seen even in high-noise environments. This helps to prevent any unforeseen ammonia hazards that may occur if not discovered quickly.

However, the airflow has ceased, and the removal efficiency of Carbon Dioxide (CO2) has decreased. Therefore, frequent inspections are needed to ensure performance with routine inspections and cleaning of the internals. For more information or to learn more, contact the professionals at DeLoach Industries Inc. at (941) 371-4995.