The operation of steam-generating boilers and the process of removing dissolved gases from the feed water is of utmost importance.

The operation of steam-generating boilers and the process of removing dissolved gases from the feed water is of utmost importance.

Deaeration is essential in the boiler system process.

Deaeration involves removing oxygen (O2) and carbon dioxide (CO2) from the water. Removing oxygen and carbon dioxide from the water before it enters the boiler system is essential. This prevents corrosion of the boiler system components and reduces costly maintenance and repairs to your system.

Oxygen and carbon dioxide can corrode and destroy metal components of the boiler system.

Corrosion can be costly to repair or replace. This is due to oxygen (O2) and carbon dioxide (CO2) not being removed from the water.

In order to avoid unwanted corrosion, it is necessary to treat the water before it enters the boiler system. This can be achieved through different techniques, including deaeration, chemical treatment, or mechanical filtration.

The deaeration process typically requires a deaerator. This device combines heat and vacuum to remove dissolved gases from water. The deaerator reduces the amount of dissolved solids in the water.This can improve the efficiency of the boiler system. Neglecting regular maintenance and inspection of the boiler can lead to severe corrosion damage and operational issues.

These issues include reduced efficiency, increased fuel consumption, and increased risk of breakdowns. In the worst case, it can even lead to the complete failure of the boiler, resulting in costly repairs or replacement. At DeLoach Industries, we understand the significance of deaeration in preserving the longevity and efficiency of boiler systems.

The feed water must have its dissolved gases removed properly.

Otherwise, it can cause serious damage to the boiler's parts.

Oxygen and carbon dioxide can initiate corrosion reactions when they come into contact with metallic equipment. As a result, rust or oxides begin to form, attaching themselves to the walls of the piping and tubes. Over time, this accumulation can lead to the complete shutdown of the boiler, jeopardizing its functionality and safety.

Dissolved oxygen is a major gas that causes worry in boiler systems. Its presence can speed up corrosion, especially in places with high temperatures or increased water flow. To minimize the risk of damage caused by corrosion, it is important to eliminate oxygen through deaeration. Deaerators play a vital role in achieving this objective.

Deaerators are specialized equipment designed to remove dissolved gases from the feed water. These devices often utilize steam to enhance the efficiency of gas removal. The deaerator eliminates dissolved oxygen and carbon dioxide from the water.

The prevention of corrosion is achieved by utilizing a variety of methods, including mechanical and thermal processes. The deaeration process is essential for corrosion prevention.

It reduces the oxygen content in the boiler to a minimum of 7 parts per billion (ppb) by weight. Low oxygen content helps optimize boiler performance and extend its life. It also reduces the risk of corrosion and other damage caused by oxygen exposure.

Mechanical methods can reduce the risk of corrosion. These include protective coatings and sacrificial anodes. Installing these can provide extra protection.

Thermal methods can reduce the risk of corrosion. These methods include the use of inhibitors and maintaining proper boiler temperatures. By utilizing a combination of these methods, corrosion can be effectively prevented and boiler performance and longevity can be maximized.

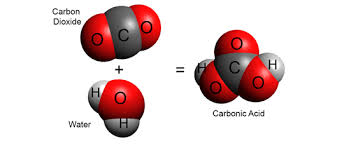

In addition to oxygen removal, the elimination of carbon dioxide is equally important. When carbon dioxide dissolves in water, it forms carbonic acid, which can intensify the corrosion process. To address this, deaerators incorporate techniques to remove carbon dioxide as well, ensuring comprehensive gas removal.

A decarbonator is a system that is used to remove carbon dioxide from feed water without the need for steam. This makes it a more cost-effective and efficient option for systems that primarily require carbon dioxide removal.

The decarbonator uses a process to remove carbon dioxide from the feed water.

It passes the water through a series of filters and chemical treatments.

This process removes the carbon dioxide from the water. The carbon dioxide is then collected and stored for later use or disposal. The decarbonator is reliable and efficient for removing carbon dioxide from feed water. This makes it an ideal choice for systems that need carbon dioxide removal.

At DeLoach Industries, we are committed to providing comprehensive solutions for boiler systems, including effective deaeration processes. Our team is highly knowledgeable and experienced in designing and installing deaeration systems. We customize these systems to meet the specific needs of our clients.

We understand the harm caused by dissolved gases on boiler performance. We strive to ensure the long-term reliability and integrity of your boiler systems.

We encourage you to stay up to date with the latest industry advancements and practices. Subscribe to our monthly newsletter to gain a better understanding.

This resource provides valuable insights, updates, and technical information. It helps you stay informed and up to date with the ever-changing field of boiler technology and maintenance.

DeLoach Industries offers expert knowledge of boiler systems and related technologies. Our blog page features regular technical blogs written by our experts. These blogs provide in-depth information and expertise.

Protecting your boiler from corrosion and maintaining its operational efficiency is paramount.

Prioritize effective deaeration processes. Utilize the expertise of professionals. This will ensure optimal performance and longevity of your boiler systems.

Contact the professionals at DeLoach Industries Inc. for more information. Learn more about our industrial water and wastewater services and solutions. Call (941) 371-4995. We are here to assist you in safeguarding your boiler systems and maximizing their performance.