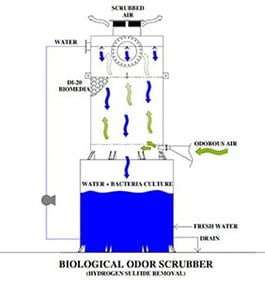

A Biological Scrubber is a wet odor control scrubber that treats and removes contaminants from an air stream.

A Biological Scrubber is a wet odor control scrubber that treats and removes contaminants from an air stream.

It utilizes caustic typically to control the pH of the re-circulation solution. There are several types of odor control and chemical fume scrubbers on the market today. Each plays a role in treating noxious or corrosive gases in the industry.

Biological scrubbers are used in municipal applications to treat low and high hydrogen sulfide (H2S) gas levels. This colorless gas is removed from the water or wastewater treatment process.

Water treatment equipment such as “degasification” or “decarbonation” towers.

Strips the hydrogen sulfide gas from the treated wastewater and exhausts the gas from an exhaust port. These gases are captured and sent to the biological scrubber via an air duct system. The health effects of hydrogen sulfide can cause eye irritation, loss of appetite, and fluid in the lungs. Hydrogen gases are captured at a wastewater treatment process, including treatment facilities, lift stations, or head-works facilities. The PVC or FRP duct system sends the gases to the biological scrubber.

How does a Biological Scrubber work?

A biological scrubber utilizes tiny microorganisms (bacteria) to break down and digest contaminants. The bacteria feed on the contaminants and utilize this as a feed source to live and grow. When utilizing a biological scrubber for hydrogen sulfide (H2S) treatment, the by-product waste is acid from the digested H2S. This lowers the pH and requires the use of caustic to buffer the water and nutrient solution that is recirculated within the scrubber to maintain a neutral pH. The captured gas containing contaminants enters the bottom of a vertical biological scrubber. Similar to how the gas enters any other type of chemical scrubber or single or dual pass odor control scrubber.

The gas stream travels upward. Passes over a media bed that has been cultured to grow live microorganisms. A biological odor control scrubber already has “artificial intelligence” because of the millions of microbes colonies it supports.

A chemical scrubber or an ammonia scrubber, the biological media bed, is specially designed to support the bacteria colony growth.

It allows air movement with the least amount of back pressure. A biological scrubber requires far fewer media packing to treat the air stream's contamination. Due to the contaminants being consumed and digested as opposed to oxidized.

The best application for a Biological Scrubber is when?

The gas concentration for a biological scrubber is relatively low, < 10 PPM, and the concentration should not fluctuate or vary rapidly.

Chemical scrubbers can adjust quickly to changes in concentrations within the airflow. They rely upon the immediate increase in chemical reagents like caustic or acid. A biological scrubber needs to adjust more slowly over time to acclimate. Due to the size of the bacteria colony or the risk of unbalancing the scrubber.

When levels remain constant, the bacteria colony acclimates to the amount of contaminant it can consume and treat. The caustic feed rate is adjusted accordingly. With a sudden or rapid increase. Insufficient bacteria may consume the increased contaminant load, allowing a breakthrough (untreated contaminants leave the scrubber) to occur.

Biological scrubber technology is the treatment of off-gases. If the concentrations are known and not expected to change and are under ten ppm. When fluctuations are expected, additional nutrients can be added to support a larger bacteria colony.

Quite often, the ability to remove the odor is not the most critical factor behind the technology selection. Several methods of treating odors in wastewater applications, but this short overview focuses primarily on biological odor control scrubbers. To treat hydrogen sulfide (H2S). Use either “chemical” or “biological,” both types have been widely used over the past decade in municipal, industrial, and petroleum markets.

DeLoach Industries, a leader in odor control and off-gas treatment, designs and manufactures various systems. Incorporating artificial intelligence (AI) into its systems to improve component-to-component communications and reporting on all critical functions.

If an operator is alerted that there is too much acid or not caustic enough in a supply tank. Or the scrubber contacts the local supplier or support facility to respond before a problem becomes critical.

Understanding the parameters of the air waste stream you need to treat before selecting the right type of scrubber.

Analyze the odor gases to understand the total loading rate and what type of chemicals create the odorous gases.

Work with manufacturers with design experience. You will often find methane and hydrogen sulfide combined with other organics. Understanding the chemical matrix of the gas is the first step in the selection process.

Make sure you obtain more than just one air sample over several periods before selecting what technology, design, and size of the odor control scrubber or air emission scrubber you need.

If you are treating another form of volatile organic chemical (VOC) gas stream. After you collect your data. Check if you have concentrations that vary widely over a day or even an hour with more than a 5% change. A chemical scrubber may be your best choice.

Biological scrubbers perform best when the concentrations remain steady and do not fluctuate. Concentrations change rapidly. Biological growth cannot adjust fast enough. The scrubber will experience a “breakthrough” of untreated gases unless it is a two-stage scrubber with a carbon polishing unit.

Concentration levels fluctuate. A wide variety of compounds containing any types of contaminants that may harm the bacteria colony in the gas mixture.

A chemical scrubber (single or dual pass) utilizing caustic or chlorine (for hydrogen sulfide) is often the best selection.

Two components of the selection process. The annual operating costs of the scrubber and what type of service the scrubber will need.

Suppose the scrubber is located where there is no active operator, and it may sometimes be left unattended.

It can drive the decision back toward selecting a biological scrubber. It has fewer components that need maintaining and typically only requires caustic for pH control and occasionally a nutrient feed supply. Gather as much information on the specific location and obtain good analytical data before making the final selection for your treatment plant.

Receive Your Free Odor Control E-Book