Industrial water systems use water filters to reduce the level of solids in water from:

- Industrial

- Semiconductor

- Manufacturing

- Refining

- Oil and Natural Gas Production Processes

The wastewater may contain harmful chemicals to humans, plants, or animals. Three types of filters are commonly used in industrial settings:

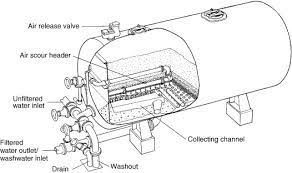

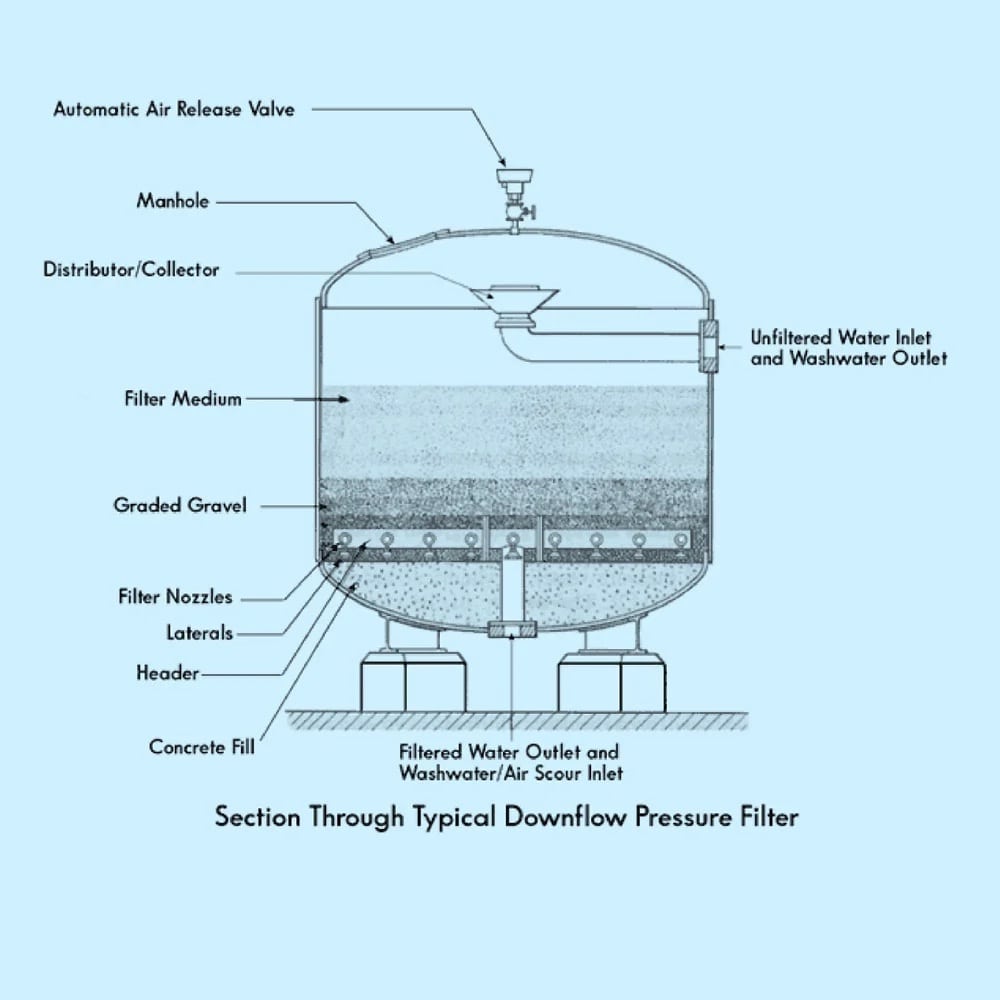

Gravity filters, pressure filters, and constructed wetlands. Pressure filters have two variations: multimedia and higher-pressure micron or cartridge filters. Constructed wetlands or natural filters are not often utilized in industrial processes. Based on the requirements to obtain environmental permits and safeguard the ecosystem.

There are many benefits to pressure filtering systems in industrial wastewater. Pressure filters can remove particles down to 0.3 microns in size. They don't clog up as quickly as other filter types, and it's much faster than other types of filtration methods.

Pressure filtering is also very cost-effective because it uses less energy than other methods. Look no further if you're looking for a high-quality industrial water filter that cuts down on operating costs!

Pressure Filters (Multimedia type) are often used in industrial settings to filter particulates down to 15 microns in size.

They're also very cost-effective due to their energy; pressure filters utilize much less energy than other filtration methods. Pressure filters can include multimedia, a mixture of gravel and sand, multimedia, gravel, sand, and anthracite, or multimedia, which combines gravel, sand, greensand, and anthracite filter media. The variations are dependent on the applications and the need.