Odor control in a manufacturing facility is essential.

It prevents potential health risks and discomfort caused by the spread of chemicals, vapors, and fumes. Additionally, excessive vapors can hinder the efficiency of exhaust and natural ventilation systems.

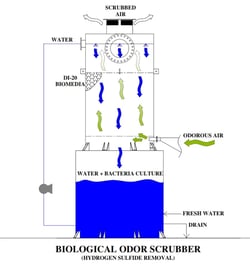

One effective solution for addressing odor issues is the installation of an Odor Control Scrubber Tower. These towers are part of the ventilation system in manufacturing plants and chemical processing facilities.

Odor control scrubbers help to remove noxious fumes and odors from exhaust and air streams. This is an effective way to improve air quality. This process involves utilizing an activated carbon filter and an ionic air filter

Key Considerations for Installing an Odor Control Scrubber Tower:

Health and Safety of Workers:

Industrial environments pose risks of exposure to hazardous fumes and gases for workers. Unhealthy odors emitted in high concentrations can jeopardize their well-being and safety. In some cases, these gases may even be combustible, adding an extra level of danger.

Odor control scrubber towers remove gases from the contaminated air, ensuring a safe working environment. These towers reduce the risk of health issues such as nausea, headaches, allergy symptoms, eye irritation, and loss of consciousness. This helps maintain worker productivity and prevents sickness caused by toxic fumes and gases.

Environmental Considerations:

While protecting workers from harmful fumes is paramount, safeguarding the environment is equally important. Odor control scrubbers find applications in various industries, including petrochemical refining, pharmaceuticals, food and beverage, paper manufacturing, mining, and chemicals.

Choosing the right odor control scrubber type is essential. Choosing the right odor control scrubber can help lower operational costs, reduce maintenance efforts, and prevent corrosion. DeLoach Industries' experts can help you make the right choice. If you need more information about odor and water treatment management, please contact them.

Scrubbers help manage odor control and reduce emissions. This contributes to a cleaner environment. It also minimizes sludge production, and potential environmental hazards and maximizes air cleaning, carbon dioxide removal CDR.

Continuous Monitoring of Hazardous Gases:

Continuous Monitoring of Hazardous Gases:

Moreover, the scrubbers utilize economical carbon filters that require very little upkeep.

Certain gases require continuous monitoring, a task well-suited for activated carbon odor control scrubber towers. Various industries use activated carbon to remove emission odors. This solution is cost-effective and requires low maintenance. It is especially useful for industries that emit strong odors that can damage the environment and the Earth's atmosphere.

Activated carbon efficiently removes hazardous vapors such as ammonia, hydrogen sulfide, and hydrogen cyanide. And is common in the petrochemical industry, where hydrogen sulfide levels are typically high.

Activated carbon is treated with extremely high-temperature steam. This creates a highly porous material with millions of pores. These pores are capable of adsorbing impurities that are many times larger than the pores themselves.

Reduced Operating Costs:

Odor control scrubbers present a more economical alternative compared to other options. They can be integrated into existing systems without significant expenses.

In case of equipment malfunctions, the impact is limited to specific areas, ensuring the overall plant's reliability. Scrubbers can be especially beneficial in areas with a high risk of explosions. They can reduce the amount of gas entering the plant if there is a leakage incident.

The carbon filters used in the scrubbers are cost-effective and require minimal maintenance. Scrubbers are ideal for industrial environments with high concentrations of harmful gases. Examples of these gases include paint, rubber, plastic, and chemical manufacturing.

Importance of Ventilation and Odor Control:

Ventilation systems and odor control work hand in hand to maintain clean and safe air for workers. The fans supply air to the workspace and can be contaminated with dust, exhaust gases, smoke, and odors.

Air scrubbers are part of the exhaust system. They effectively remove contaminants and gases. The ventilation system then expels the polluted air from the premises.

The cleanliness and safety of an environment depend on the amount of contaminated air and gases entering it. The number of fans needed to achieve this depends on the volume of these contaminants. Precise calculations are necessary to allocate the appropriate amount of air for both ventilation and cleaning purposes.

Reduced Fire and Explosion Risks:

Higher concentrations of harmful gases elevate the risks of fire and explosions. Odor control scrubbers mitigate these risks by removing harmful gases from the air, ensuring a safer working environment.

Air scrubbers extract contaminants and gases. The ventilation system then expels the impure air from the room. This reduces the chances of fire or explosion incidents.

The odor control scrubber is essential for keeping air quality high. It captures polluted air and sends it through an ionic air filter. This process is efficient and effective.

This filter removes particulate matter and odors. The air passes through the carbon filter. Gases are trapped in the filter through adsorption. Finally, the clean air exits the scrubber tower.

In conclusion, installing an odor control scrubber tower in your company can be beneficial. It offers efficient solutions for handling gases that are difficult to remove with standard air filters. These towers remove many contaminants. This provides several advantages, such as: - Worker safety - Environmental protection - Reduced fire and explosion risks - Lower operating costs - Improved ventilation efficiency.

Proper and safe handling of toxic chemicals and fumes is crucial. The Agency for Toxic Substances and Disease Registry provides useful information and materials on managing and regulating odor control.

Do you have questions about controlling odors with scrubbers or managing water treatment? Reach out to the experts at DeLoach Industries at 941-371-4995.