In the United States manufacturing industry, an astonishing 400 million gallons of water per day (MGD) is consumed to generate steam.

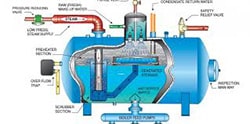

Out of this amount, approximately 60 MGD is sent to blow-down drains, while another 300 MGD is used for direct injection of steam. The common denominator in all of these processes is the need for purified and treated water. Without proper treatment, manufacturers would face frequent shutdowns and increased capital expenditure, significantly impacting their cost of goods. One effective method of water treatment to protect boilers is through degasification and deaeration.

Degasification towers play a crucial role in removing harmful gases such as hydrogen sulfide (H2S), carbon dioxide (CO2), and often dissolved oxygen (DO). The elimination of these corrosive gases is vital for enhancing the lifespan and efficiency of boiler systems. If these gases are allowed to remain in the boiler feed water, particularly carbon dioxide (CO2), it can lead to disastrous consequences, including higher operating costs and reduced system longevity. Carbon dioxide (CO2) can convert into carbonic acid, creating a corrosive environment for the boiler and other critical components. In cases where an ion exchange process is implemented prior to the boiler, the presence of carbon dioxide (CO2) can drastically increase regeneration costs as the resins are consumed. By removing carbon dioxide (CO2), the life of the resin is extended, and the pH of the water is elevated, reducing the need for additional chemicals and further lowering operating costs.

The appropriate type of degasification tower selection depends on specific applications, site conditions, and water chemistry.

Typically, a degasification tower is positioned downstream or post-treatment of a reverse osmosis system before an ion exchange cation or anion system. This strategic placement ensures optimal water treatment to protect the boiler and feed system while maximizing reliability and cost-effectiveness.

There are two main types of degasification towers: "Induced Draft" and "Forced Draft." An Induced Draft tower pulls air up through the tower, allowing the gases to pass through the blower. On the other hand, a Forced Draft tower pushes air up through the tower, with the blower exposed only to fresh intake air. In most industrial applications, the Forced Draft type is preferred. At DeLoach Industries, we have tested both types of degasification towers in conjunction with our pre- and post-treatment systems, yielding similar results. However, the Forced Draft system offers added flexibility, allowing the exhaust air to be directed outside the facility or into an additional treatment system for air emission control when required.

For more information on industrial boiler feed water treatment and the selection of degasification towers, we invite you to contact the professionals at DeLoach Industries Inc. Our experienced team can provide you with valuable insights and guidance tailored to your specific needs. Reach out to us at (941) 371-4995 and discover how we can help you achieve optimal water quality and system performance.

In conclusion, effective water treatment is crucial for industrial boiler feed water to ensure operational efficiency and minimize costs. Degasification and deaeration play a vital role in removing harmful gases, protecting the boiler, and preserving critical components. Manufacturers can optimize their operations and maintain high-quality steam production by selecting the appropriate degasification tower and implementing comprehensive water treatment measures. Contact DeLoach Industries Inc. at (941) 371-4995 to learn more and take proactive steps towards reliable and efficient boiler feed water treatment.

Receive Your Free Odor Control E-Book