Have you ever walked on a sidewalk or in a parking lot and passed by a lift station or manhole and noticed a smell so bad you thought you were going to pass out?

Most people who encounter these types of odors do not live in the world of designing and building odor-control treatment systems. For those of us who do we fully understand that when we encounter such a noxious smell it most likely needs an odor control system. It does not matter if the odorous smell is coming from an industrial water treatment process, food and beverage plant, wastewater plant, or from the off-gas of a “degasification process”. All of these types of industries and many more can generate odors and quite often these noxious odors must be addressed and treated because of either safety or public outcry. Many times odorous gases are generated as the result of processing and purifying drinking water. When water contains contaminants like hydrogen sulfide (H2S), carbon dioxide (CO2), or ammonia (NH3) there is a need to treat and remove these harmful elements from the water.

Odors come from many sources

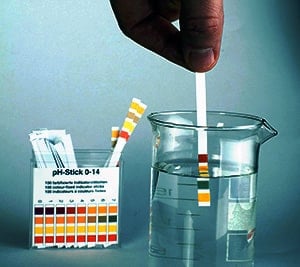

When processing and purifying drinking water which requires pH adjustment by adding acid to lower the pH and allow for the removal of hydrogen sulfide (H2S) which will not convert at higher pH levels. After the pH level is properly adjusted the hydrogen sulfide can be removed by degasification. After the degasification process the pH will rise in the water from the removal of the carbon dioxide (CO2) and if the pH remains slightly acidic then caustic is normally injected into the water stream to raise the pH back up to a neutral level of 7. This entire required process to purify the water is what generates the odor and creates the requirement for an odor control scrubber. Odor control scrubbers may utilize chemicals such as acid and caustic to treat the air gas noxious odor or it may be a biological Scrubber that consumes the contaminants within the noxious gas air stream including ammonia and hydrogen sulfide. Noxious or corrosive odorous gases are not always from wastewater treatment plants or underground lift stations that are commonly referred to as “wet wells”. Quite often odors are generated during manufacturing or food processing as well as from the efforts just mention in a municipal water treatment and purifying plan. During the period of pH adjustment hydrogen sulfide (H2S) and other odorous substances can be released by means of Decarbonation or Degasification. Some odors have a pungent smell and other odors are harmful corrosive gases that must be contained to protect the surroundings or even human life. There are many types of odors and off gases that must be contained, captured, treated, or neutralized. Understanding the; who, what, where, and why, first will normally put you on the road to selecting the right solution for odor control.

-1.jpg)