When it comes to removing hydrogen sulfide (H2S) from water through the process of degasification.

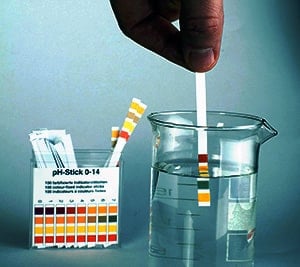

It is crucial to ensure that the pH of the water is properly adjusted prior to treatment. This step becomes more complex if you are not already pre-treating water for membrane filtration or softening. The reason behind this is that when the pH of water rises above 5.5, it becomes increasingly challenging to convert H2S or sulfides into a gaseous phase, which is necessary for their removal through the degasification process utilizing a degasifier.

At a pH of 7, the conversion rate drops significantly, and a standard degasification tower can only remove about 80-85% of hydrogen sulfide (H2S), leaving behind worrisome levels of this compound in the water. However, by lowering the pH to 5.5 (or at least a pH of 6), the removal efficiency dramatically increases to 99% in most cases. In situations where high water quality is demanded, such as in breweries or canneries, removal rates as high as 99.99% can be achieved by carefully adjusting the pH.

Leaving excessive amounts of hydrogen sulfide (H2S) or sulfur in the water can lead to various additional problems with water quality, including unpleasant taste and odor. Moreover, it can cause fouling and corrosion of the primary equipment and even the facilities themselves. The negative consequences of inadequate hydrogen sulfide removal underline the importance of addressing this issue effectively.

If you would like to obtain more information or learn about the various solutions available, we recommend reaching out to the professionals at DeLoach Industries Inc. They have extensive expertise in the field and can provide you with valuable insights and guidance. Feel free to contact them at (941) 371-4995 to discuss your specific needs and find the most suitable approach for hydrogen sulfide removal from your water in your water treatment system.

By addressing the pH adjustment requirement and ensuring effective degasification, you can significantly improve the overall quality of your water supply. Investing in proper treatment measures not only enhances the taste and smell of the water but also safeguards the longevity and functionality of your equipment and infrastructure.

DeLoach Industries Inc. is renowned for its commitment to excellence and customer satisfaction. Their knowledgeable team is well-equipped to assist you in finding the most effective solutions for hydrogen sulfide removal, tailored to your unique circumstances. Don't hesitate to get in touch with them today to explore how they can help you achieve optimal water quality and mitigate the potential challenges associated with hydrogen sulfide contamination.

In conclusion, when dealing with the removal of hydrogen sulfide (H2S) from water through degasification, ensuring proper pH adjustment is essential for successful treatment. Adjusting the pH to an ideal level of 5.5 or at least 6 significantly improves the removal efficiency, offering rates as high as 99%. Neglecting this crucial step can result in compromised water quality, fouling, and corrosion of equipment and facilities. For expert guidance and solutions tailored to your needs, contact DeLoach Industries Inc. at (941) 371-4995, and take proactive steps toward ensuring clean and high-quality water.

Receive Your Free Odor Control E-Book

Related Blog: Degasification Tower Design: Square vs. Round?