To enhance and control the production and quality of seafood grown and harvested.

The industry increasingly focuses on constructing in-house aquaculture fish farms, commonly called aqua farming. The most popular species of aqua farming continue to be salmon, tilapia, catfish, and carp. Increased interest in the United States has developed aqua farming facilities in southern Florida with favorable climate and water conditions.

When considering several types of fish species to grow for harvest, it is important to remember the need to control the water quality. If the aqua farm is intended to utilize man-made tanks, they will depend upon a constant flow of incoming water. If the aqua farm focuses on salmon, the water quality and temperature play a major role in the operation's mortality rates and production yields.

Having water with too high of hydrogen sulfide, carbon dioxide, total Organic carbons, and even turbidity can increase mortality rates among the younger fish species and is especially critical to salmon.

Having high levels of metals

Such as Iron that is identified as either “ferric” (Fe-) or “ferrous” (FE+2) and is naturally occurring within the Florida waters and other parts of the US will cause significant damage to young salmon species because the metal accumulates within the gills of the fish causing suffocation. Other metals are also detrimental to fish, including copper, aluminum, arsenic, cadmium, chromium, Lead, manganese, and mercury, to name a few, and the water quality must be evaluated and tested in the early stages of design to anticipate the required types of process systems needed.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

hydrogen sulfide (H2S),

pH levels,

Alkalinity,

Decarbonation,

carbon dioxide,

oxygen,

decarbonator,

degasifier,

carbonic acid,

H2S Degasifier,

Aqua Farming,

Fish Farming,

Aquaculture,

Pisciculture

Water Treatment

When planning and designing a man made on land aquaculture or pisciculture facility.

The most important key element is the quality of the water. For operations developing in Florida or the Caribbean it is important to remember that water quality varies in Florida and other states in the US and typically requires some type of water treatment. For fresh and salt water land based farms that utilize tanks located inside of a building the water needs to be treated and pure from any naturally occurring contaminants such as hydrogen sulfide (H2S), iron (Fe+), and even carbon dioxide (CO2).

The most cost effective way to treat incoming water for aquaculture farming and remove hydrogen sulfide, iron, and lower carbon dioxide is the use of a “degasification” tower. A degasification tower or degasifier is a piece of process equipment. Degasifiers can also be referred to as a “decarbonator” or “air stripper” or even “aeration tower”. The degasification tower is a vertical column designed to remove certain types of contaminants by “stripping” the molecules of converted gases and expelling them from the water as a gas. The science is based upon “Henry’s Law” and it relies upon the disproportionate varying vapor pressures of gases.

If the incoming raw water contains levels of sulfides or hydrogen sulfide gases it is recommended to remove the hydrogen sulfide to improve the water quality and reduce the risk of the development and formation of bacteria that can thrive on the Sulfur. In addition hydrogen sulfide is corrosive and will cause harm to other components within the process if left untreated. It is important to adjust the pH of the raw feed water prior to degasification to ensure full conversion of the sulfides into hydrogen sulfide gas (H2S) to enable the degasification process to perform and remove up to 99.99% of the harmful contaminants without adding additional chemicals. This saves money and improves quality of the product!

Read More

Topics:

water quality,

degasification,

pH levels of water,

water treatment,

hydrogen sulfide (H2S),

pH levels,

Alkalinity,

Decarbonation,

Caribbean,

carbon dioxide,

decarbonator,

degasifier,

gases,

carbonic acid,

H2S Degasifier,

Aqua Farming,

Fish Farming,

Aquaculture,

Pisciculture

DeLoach Industries made history in 1977 at the City of Cape Coral Florida water treatment plant with its large scale “degasification towers” connected to what was to become the first municipal water treatment facility in the United States to deploy the use of reverse osmosis on a large-scale production municipal treatment plant.

The Cape Coral water treatment plant for came online in 1977 and produced 3 million gallons of water per day (GPD) or 11.35 liters of purified and treated water utilizing the “reverse osmosis” process. By 1985 the plant had expanded as it kept up with growth to produce 15 million gallons per day making it at the time the world’s largest “reverse osmosis” water treatment plant facility.

Read More

Topics:

water quality,

pH levels of water,

water treatment,

advanced treatment solutions,

water plant,

hydrogen sulfide (H2S),

pH levels,

Alkalinity,

scaling,

chlorine,

caustic,

Decarbonation,

wastewater,

carbon dioxide,

degasifier,

RO membrane,

RO system,

H2S Degasifier

Caustic solution for Sodium hydroxide water treatment of Sodium Hydroxide

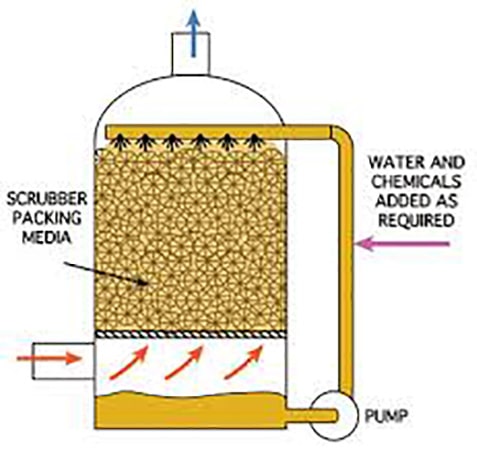

There are many industries that require the use of a caustic scrubber which is considered a chemical scrubber and they range from the municipal industry, mining, semiconductor markets, pulp and paper, and chemical refining. There is a wide variety of industrial processes that generate noxious or corrosive off gases that require treatment and a comparison is made between biological Vs. chemical. Often biological scrubbers have limitations due to concentrations, composition, or temperature of the contaminants and if the gas stream contains acid fumes then a biological scrubber is quickly ruled out.

The odor control selection is often fraught with choices of capital cost over operational cost and quite often comes down to familiarity from the designer or purchaser. It is always a good idea to freshen up the industrial odor control the do’s and don’t’s before selecting the final solution. If the off-gas source that needs to be treated is hydrogen sulfide (H2S) or some other type of gas stream produced by an acid or ammonia it will often require neutralization for human health reasons and to protect equipment or may be required to meet regulatory compliance. Caustic scrubbers may be either vertical or horizontal by design, but both utilize a packed media bed of either random packing or trays to allow the gas fumes to meet the recirculating caustic solution which then forces the reaction to occur.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

caustic,

wastewater,

carbon dioxide,

degasifier,

gases,

caustic solution,

sodium hydroxide water treatment

What type of Odor Control Scrubber do I select?

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

pH levels,

degasifier,

gases

The type of Odor Control Wet Scrubber selected for the treatment and neutralization of Ammonia (NH3) gases depends on several variables, including the type and source of the ammonia gas and whether or not it is “Free” ammonia and or unionized.

Ammonia is a very miscible and stable molecule with solid hydrogen bonds, making it very soluble in water and difficult to treat without using a properly designed and sized ammonia scrubber. The concentrations, air flow rates, temperature of the gas stream, and chemical reagents being utilized, such as caustic to remove and then treat the ammonia, all play a significant role in the removal efficiency of the ammonia gas scrubber system. Unlike other types of “odor control scrubbers,” an ammonia scrubber is much more sensitive to variables such as the gas stream temperature because of the solubility of ammonia.

Ammonia is produced from nitrogen and hydrogen

the process is called the Haber Process by combining nitrogen with air and adding pressure, you can make ammonia.

It takes about 200 atmospheres of pressure, and the process varies from refinery to refinery. Still, on average, you can only make approximately 15% of ammonia during each pass which takes multiple passes to achieve the 15%. The reaction to make ammonia is exothermic when produced in a refining process.

However, ammonia is also formed in nature in smaller quantities. Most ammonia (90%) is utilized for fertilizer production, but ammonia can be found in food, pharmaceutical products, and cleaning supplies. When ammonia gas is released into the air, it has a very noxious and pungent odor that can be dangerous to inhale, so often, odor control scrubbers are required to capture and treat the ammonia gas.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

pH levels,

Decarbonation,

dissolved gases,

wastewater,

degasifier,

gases,

H2S Degasifier,

Ammonia

The water treatment industry has developed and evolved over the years to continue to find new ways to produce degassed water,

Read More

Topics:

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

water plant,

safety,

hydrogen sulfide (H2S),

Chemical Odor,

media packing,

pH levels,

Decarbonation,

dissolved gases,

wastewater,

Global,

carbon dioxide,

decarbonator,

degasifier,

gases,

RO membrane,

H2S Degasifier,

degassed water

Water treatment in the Caribbean poses unique challenges due to the specific characteristics of the region.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

water plant,

odor control scrubber,

pH levels,

Alkalinity,

Recycling,

Caribbean,

Global

Do you need to remove or increase your reverse osmosis system's hydrogen sulfide removal efficiency?

The industrial water treatment market has many forms of water treatment processes. Most of us would agree that maintaining high water standards and quality requires using multiple treatment systems to achieve results. Let’s face it, we do not win or get a “that a boy” when we design and build the best reverse osmosis system.

When we turn the brand-new water system on, the water has a "rotten egg odor." Yes, that is an embarrassing moment!

The problem is we typically design around what we can see or read. When was the last time you reviewed a water sample that provided details of how much-dissolved gas was in the water? Most likely never. A typical water treatment system may deploy reverse osmosis as the primary treatment method, and why true RO will remove particles that have size and weight (ions and molecules) typically defined as a certain size (micron), but RO does nothing to remove the dissolved gases that are already entrained within the water naturally or were created by adjusting the pH.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

hydrogen sulfide (H2S),

pH levels,

Alkalinity,

Langilier index (LSI),

H2S Degasifier,

H2S H2O,

removing hydrogen sulfide in water

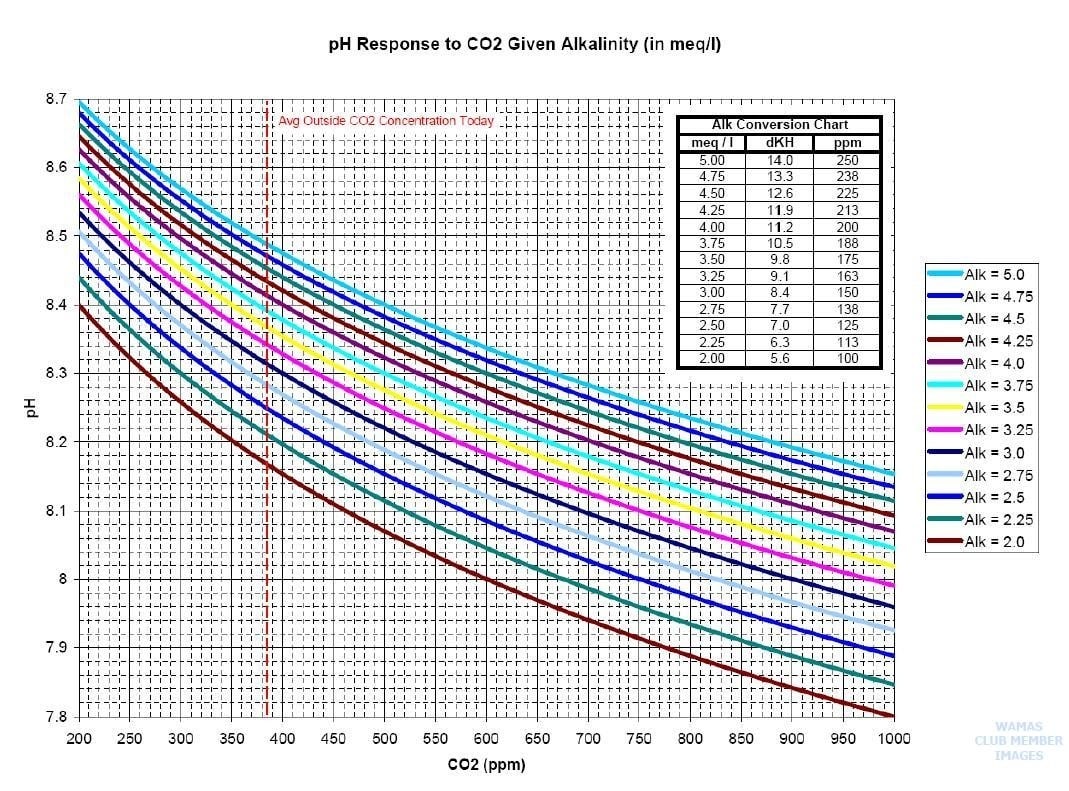

Decarbonation is a critical process in water treatment, and understanding the impact of alkalinity is essential for its successful implementation.

Read More

Topics:

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

bicarbonate,

phosphate levels,

Silicate,

Borate