Avoid problems with calcium chlorite and corrosive gasses with your odor control scrubber.

When planning or designing an odor control system, one should pay close attention to several key variables that can cause havoc on a chemical odor control scrubber when trying to treat hydrogen sulfide or ammonia gases. The need for odor control occurs in many different forms. It is essential to understand the process that is creating the odorous or corrosive gas and the need for odor control & air emissions treatment.

First, begin to identify

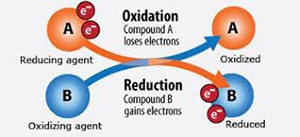

all the potential obstacles that may creep up later after the chemical odor or corrosive gas control system goes online, like acid or caustic consumption. For example, chemical odor control systems designed for water treatment for the municipal industry are typically needed and attached to a degasification or decarbonation process, often needed to treat hydrogen sulfide (H2S). However, designers often may not pay close enough attention to the type of water process available for “make-up” water for the chemical scrubber. The addition of caustic can create scaling or fouling. This unknown variable of the makeup water quality can lead to a complete tower shutdown if the chemical scrubber distribution and media bed scales or fouls. The most commonly used chemicals for a hydrogen sulfide (H2S) scrubber are either chlorine in the form of sodium hypochlorite or caustic in the form of caustic soda. Both of these chemicals are common to a water treatment facility and are already in place to adjust and control pH.

The makeup water plays a significant role in the operation of a chemical scrubber.

When water containing high hardness levels is used as the source for the makeup water, your chemical scrubber can become fouled, and scaling can occur in a matter of hours, depending on the alkalinity and salts within the water. Solidification can occur from the scaling when combining sodium hypochlorite and raw feed water at specific pH ranges and these ranges are usually the range needed to achieve peak performance. Calcium chloride will form, and your chemical odor control scrubber will become a solid chunk of calcium chlorite making, making the ability for water or air to pass freely through the media packing next to impossible. No matter what type of media packing is utilized in the odor control or gas scrubber, it can foul and scale if the water chemistry is incorrect. Trust me when I say “been there and done that”! I have seen operators who have allowed a chemical scrubber to become out of balance with pH control and completely solidify the tower column to the degree that neither air nor water passage is possible. The problem can still occur with ammonia scrubbers but are different with different sets of parameters.

Read More

Topics:

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

odor control scrubber,

hydrogen sulfide (H2S),

calcium carbonate,

media packing,

pH levels,

Alkalinity,

Langilier index (LSI),

scaling,

chlorine,

caustic,

ION Exchange Resin,

Safe drinking water,

dissolved gases,

De-Aeration,

carbon dioxide,

oxygen,

degasifier,

gases,

H2S Degasifier,

calcium chlorite

The water treatment industry has developed and evolved over the years to continue to find new ways to produce degassed water,

Read More

Topics:

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

water plant,

safety,

hydrogen sulfide (H2S),

Chemical Odor,

media packing,

pH levels,

Decarbonation,

dissolved gases,

wastewater,

Global,

carbon dioxide,

decarbonator,

degasifier,

gases,

RO membrane,

H2S Degasifier,

degassed water

Many types of water treatment systems depend on some type of media to provide the best performance required as it relates to water treatment and waste water treatment. For use in reverse osmosis there is a reliance on membranes which act as filters to separate the solids from the water. For ion exchange there are “resins” whether AION or CATION the resins works to treat hard and corrosive water. Degasification and decarbonation towers both require an internal media and sometimes this is referred to as “Random Packing” or “Loose Fill Media” and in this process the media acts like a traffic cop directing traffic.

In this case it directs the water on its way down and through a towers internals where it is constantly reshaping the water droplets over and over again forcing gas molecules to come to the surface edge of the water where they are removed. Carbon filters also require a media which is of course “Carbon”. The carbon media acts like a sponge absorbing the contaminants that you wish to remove from the water until it is saturated and must be replaced or regenerated. Even sand filters or pressure filters require a media.

Read More

Topics:

degasification,

water treatment,

water plant,

media packing,

Decarbonation,

ION Exchange Resin,

feed water,

wastewater,

decarbonator,

gases,

RO membrane

Ten years ago if I had purposed that one day our water would have artificial intelligence I think I would have been laughed out of the industry. But now, anything you can imagine with the new electronic revolution is possible because of the current revolution referred to as “The Internet of Things” (IoT). Placing nano-size SIP (Systems in a package) into a water stream and tracking its path or location or performing inspections on critical infrastructure or equipment is now a reality.

Read More

Topics:

degasification,

water treatment,

advanced treatment solutions,

water plant,

phosphate levels,

pH levels,

Alkalinity,

Global,

decarbonator,

degasifier

One of the largest consumers of energy in the US is water and wastewater treatment plants.

Because of the need for large horsepower pumps and blowers, a municipal water and wastewater treatment plant consumes a tremendous amount of kilowatt hours of electricity. The energy cost is factored into the “cost of production” of water or wastewater treatment, and the “rate base” charge is increased accordingly to the consumer.

Does Renewable Power Work in a Water Treatment Plant?

Because solar energy is “space intensive,” you do not see a lot of solar power being deployed across the USA at water treatment plants. In our opinion, this is a mistake, and most likely, the decision was made back when solar power output was much lower. With the increased efficiency of solar panels and decreased production cost, it makes tremendous sense to revisit the use of Solar energy to offset the operational cost of a water treatment plant or wastewater treatment plant operation.

Providing solar energy for specific pieces of process equipment is also a viable option when you consider deploying solar energy. For example, operating a Degasification tower or Decarbonator utilizing 10 350-watt solar panels will generate 3500 watts during peak daylight hours and enough to offset the cost of smaller horsepower blower motors. If the solar panels are configured as a canopy, they can also provide a nice shade or protective barrier above the piece of equipment if installed outdoors, as most packed column towers are located outside.

What about other forms of renewable energy? Do they work?

At water treatment or wastewater treatment facilities. Co-generation use has been around for many years at Wastewater plant facilities wastewater treatment plants. A cogeneration unit is a combination “Generator” to produce power and a “Thermal” energy source to produce heated water. The water can be used domestically or can be used to produce chilled water with the help of a Chiller system. The wastewater treatment plant provides a critical component by producing gases such as “Methane,” which can be used as a cogeneration unit fuel source. Water treatment plants do not produce methane or other combustible forms of gases like a cogeneration plant would produce, so you normally do not see Cogeneration system units deployed at a Water treatment facility.

Read More

Topics:

degasification,

water treatment,

water distribution system,

advanced treatment solutions,

water plant,

Decarbonation,

wastewater,

Recycling,

Global,

steam generation,

steam

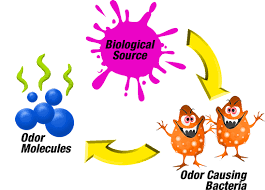

What is the best process for hydrogen sulfide treatment? Biological odor control Scrubber or a Chemical Scrubber?

Most industrial water treatment, municipalities, and private customers are responsible for water and wastewater treatment and often generate "hydrogen sulfide" off-gas odors. Professionals who either provide the design engineering or maintain the water or wastewater collection systems need to address and control "hydrogen sulfide" odors. They often find themselves in a situation where they must select what type of odor control system will perform for their customer or at their location. A chemical odor control scrubber may utilize "chlorine" or "caustic" as a scrubbing agent or just "caustic" alone. Typically, "acids" are not used when treating "hydrogen sulfide" gas, but "acid. " Acid is used when treating other types of off-gases such as ammonia. The application or process, including incorporating "artificial intelligence" into the machinery to provide more rapid responses to operators to predict maintenance and other operational functions—treating process air generated by either a "decarbonation" tower or a "degasification" tower for the removal of "carbon dioxide (CO2) or "hydrogen sulfide (H2S). It is important to understand the basics of either of the processes to allow the design professional to properly select the best type of "odor control" scrubber to utilize and make the decision to either select a chemical scrubber that uses "caustic" or "chlorine" or a biological scrubber for the treatment of the hydrogen sulfide that only requires the use of "caustic" to buffer the recirculation water. In other types of processes involving treatment, such as ion exchange, a design professional or owner must understand that the process may also produce an off-gas that requires treatment. "Ion exchange" can be used as a standalone treatment process to treat hard water utilized as a post-treatment process after reverse osmosis. Regardless of when "ion exchange" is utilized, we recommend removing the carbon dioxide (CO2) before the process to prevent the formation of carbonic "acid" and to extend and save the life of the Ion Exchange resin. It may also be necessary to adjust the pH of the water either pre or post-treatment by injecting either an "acid" solution when lowering the pH or injecting a "caustic" solution when raising the ph. It is important to remember that the efficiency of the process depends on proper pH control.

High pH and hydrogen sulfide will not convert or be removed by “degasification” and the “carbon dioxide” cannot be removed.

Read More

Topics:

odor control,

water treatment,

advanced treatment solutions,

odor control scrubber,

Chemical Odor,

gases,

Biological Odor Control Scrubber,

Biological odor control

The removal of carbon dioxide from water,

is a term called “decarbonation” and it relates to the process of stripping and removing Carbon Dioxide (CO2) from water. You will hear the term decarbonation used quite often in industrial water treatment and in high-purity water treatment. Carbon dioxide along with other elements like nitrogen and oxygen is also removed during the decarbonation process. Most gas air stripping such as decarbonation is based upon “Henry’s Law” but the removal of carbon dioxide is an exception to Henry’s Law because when water contains carbon dioxide it forms carbonic acid which can ionize into hydrogen and bicarbonate ions.

Bicarbonate ions are not bound by the rules of Henry’s Law and therefore the bicarbonate ions when formed are only slightly removed through the aeration or decarbonation process. The Carbon dioxide that remains in the water that does not form into bicarbonate can be removed by the decarbonation or aeration process. This type of carbon dioxide is called “uncombined” CO2.

Read More

Opting for the appropriate odor control scrubber can lead to significant cost savings!

We have discussed the importance of understanding the source and concentration of an odor issue before selecting the type of treatment or odor control system. In addition to these critical items is the consideration of operating costs.

Many types of odor control systems work and remove odors, but selecting and designing a system that works efficiently and effectively without breaking the bank can be challenging.

For a design professional and the system supplier, it is essential to consider what an owner, and their operators, will face to maintain the odor control system.

For example, carbon absorption has been around for many years and is a very effective method for removing noxious odors from an air stream. However, the use of carbon in municipal operations is seldom seen these days due to the extreme cost of disposal or on-site regeneration of the carbon once it has been spent. The same can be said about other odor control processes that utilize chemicals, such as potassium permanganate.

Read More

Topics:

water quality,

odor control,

water treatment,

biological scrubber,

water plant,

odor control scrubber

When do you know if your decarbonation system needs service?

When a degasification tower or decarbonator becomes fouled, several indicators identify you may have a problem or that it's time to clean your system. If the efficiency of the degasifier has dropped, you will see an increased consumption rate of chemicals. If you remove less hydrogen sulfide gas from the degasifier, chlorine consumption will increase. When you increase the amount of chemical reaction occurring in the water, you will see an increase in the TSS levels and a drop in water quality. As the H2S reacts with chlorine, more solids will form and be present in the water, and the water quality will diminish.

Another indicator of a fouling condition is the pH adjustment in the Industrial Water Treatment industry. You are required to meet the set standards. As the performance of the tower drops, the removal of CO2 will also drop, leaving a higher pH level than may be desired. A quick inspection to check out the media bed should be performed. Also, do not forget to inspect the distribution system at the top of your tower and remember that all distribution systems are not alike, and inspecting the condition of each of them may require additional effort on your part. With a header lateral system, you need to inspect the distribution nozzles, but with a Weir or Tray type, you will need to check the amount of scale or fouling building up on the Weir edge or in the bottom of the pan. If the Weir edge becomes fouled unevenly, it will create "Channeling" of the water and increase the initial hydraulic load to a concentrated point on the media bed.

Read More

Topics:

water treatment issues,

blower maintenance,

aeration,

water treatment,

advanced treatment solutions,

degasifier,

Deagasification,

decarbonation of water

Optimizing Steam Process Water Systems with Degasification Towers

Steam process water systems are integral to various industrial operations, where water is heated and converted into steam. However, ensuring the efficiency and longevity of these systems requires a comprehensive understanding of water chemistry and the implementation of proper treatment methods. In particular, the removal of dissolved gases, such as hydrogen sulfide (H2S), carbon dioxide (CO2), and dissolved oxygen (O2), is crucial. This blog post will delve into the significance of degasification towers in steam process water systems, emphasizing their role in preventing corrosion, enhancing equipment performance, and maintaining water quality in your water and wastewater systems.

The Importance of Removing Dissolved Gases

Dissolved gases in steam process water systems can have detrimental effects on boilers and other critical components. Allowing gases like carbon dioxide (CO2) to remain in the water leads to the formation of carbonic acid, creating a corrosive environment. This corrosion can damage the boiler and reduce its lifespan. Additionally, dissolved gases can impair the efficiency of the system, affecting heat transfer and leading to reduced performance.

Read More

Topics:

De-Aeration,

carbon dioxide,

oxygen,

steam,

decarbonator,

degasifier,

carbonic acid