A Biological Scrubber is a wet odor control scrubber that treats and removes contaminants from an air stream.

It utilizes caustic typically to control the pH of the re-circulation solution. There are several types of odor control and chemical fume scrubbers on the market today. Each plays a role in treating noxious or corrosive gases in the industry.

Biological scrubbers are used in municipal applications to treat low and high hydrogen sulfide (H2S) gas levels. This colorless gas is removed from the water or wastewater treatment process.

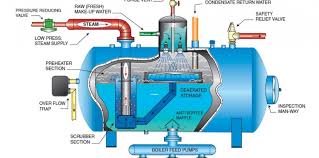

Water treatment equipment such as “degasification” or “decarbonation” towers.

Strips the hydrogen sulfide gas from the treated wastewater and exhausts the gas from an exhaust port. These gases are captured and sent to the biological scrubber via an air duct system. The health effects of hydrogen sulfide can cause eye irritation, loss of appetite, and fluid in the lungs. Hydrogen gases are captured at a wastewater treatment process, including treatment facilities, lift stations, or head-works facilities. The PVC or FRP duct system sends the gases to the biological scrubber.

How does a Biological Scrubber work?

A biological scrubber utilizes tiny microorganisms (bacteria) to break down and digest contaminants. The bacteria feed on the contaminants and utilize this as a feed source to live and grow. When utilizing a biological scrubber for hydrogen sulfide (H2S) treatment, the by-product waste is acid from the digested H2S. This lowers the pH and requires the use of caustic to buffer the water and nutrient solution that is recirculated within the scrubber to maintain a neutral pH. The captured gas containing contaminants enters the bottom of a vertical biological scrubber. Similar to how the gas enters any other type of chemical scrubber or single or dual pass odor control scrubber.

The gas stream travels upward. Passes over a media bed that has been cultured to grow live microorganisms. A biological odor control scrubber already has “artificial intelligence” because of the millions of microbes colonies it supports.