Do you need to remove or increase your reverse osmosis system's hydrogen sulfide removal efficiency?

The industrial water treatment market has many forms of water treatment processes. Most of us would agree that maintaining high water standards and quality requires using multiple treatment systems to achieve results. Let’s face it, we do not win or get a “that a boy” when we design and build the best reverse osmosis system.

When we turn the brand-new water system on, the water has a "rotten egg odor." Yes, that is an embarrassing moment!

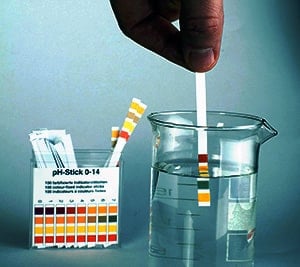

The problem is we typically design around what we can see or read. When was the last time you reviewed a water sample that provided details of how much-dissolved gas was in the water? Most likely never. A typical water treatment system may deploy reverse osmosis as the primary treatment method, and why true RO will remove particles that have size and weight (ions and molecules) typically defined as a certain size (micron), but RO does nothing to remove the dissolved gases that are already entrained within the water naturally or were created by adjusting the pH.

Read More

Topics:

water treatment issues,

water quality,

degasification,

pH levels of water,

water treatment,

advanced treatment solutions,

hydrogen sulfide (H2S),

pH levels,

Alkalinity,

Langilier index (LSI),

H2S Degasifier,

H2S H2O,

removing hydrogen sulfide in water

Choosing the Right Materials: Ensuring Certification and Performance in Water Treatment

Read More

Topics:

water treatment issues,

contact molded process,

safety,

FDA,

NSF/ANSI 61

Water treatment towers and storage tanks are high places that require special precautions when entering. While the majority of people who enter these locations for work can be trusted, there are some hazards that make it more important than usual to follow safety procedures.

These locations can get very hot and humid, and can also be filled with harmful chemicals and microorganisms that can cause serious health issues if inhaled or absorbed through the skin. Therefore, the general standard for workplace safety is much higher when entering locations like these.

Make sure you have read and understood the following information about safety when entering a water treatment plant. It will help you understand how to stay safe and protect yourself from harm when entering a water treatment plant. normal installation, maintenance, or even emergency repairs, it is often required to enter into a water treatment tower (degasifier, air stripper, decarbonator, or clear well/ storage tank). When this occurs, full safety protocols should be followed at all times, in accordance with OSHA regulations. A tower or tank B classification is a "Confined Space" location. For more information visit the OSHA confined space regulations page.

In addition, there are other safety risks that an operator or technician can be exposed to while inside these types of closed locations. The risk can come from fumes of hydrogen sulfide (H2S), chlorine from an injection line, or a lack of oxygen O2. A proper confined space permit should be prepared and only technicians with proper training and certifications should enter into these types of confined spaces.

Read More

Topics:

water treatment issues,

water quality,

odor control,

water treatment,

advanced treatment solutions,

biological scrubber,

water plant,

safety,

odor control scrubber,

hydrogen sulfide (H2S),

Chemical Odor,

media packing,

scaling,

caustic,

Safe drinking water,

dissolved gases,

wastewater,

carbon dioxide,

degasifier,

gases,

Ammonia,

what is a scrubber,

Hydrogen Sulfide formula,

Deagasification,

Filter Media,

DeLoach Industries, Inc.,

Drinking Water,

Clean Water,

Contaminated Water,

OSHA

Often times a wastewater treatment plant clarifier will need repair and retrofitting, especially in and around the weir trough.

Most clarifiers are manufactured out of steel, and over time the corrosive conditions at a wastewater treatment plant corrode and the adjustable weirs often disintegrate, making proper operation impossible. The most cost-effective method to rebuild and retrofit the clarifier weir is to utilize a fiberglass replacement. Depending on the extent of the damage, which could involve just replacing the weir plate or it could involve a more extensive process that requires replacing portions or all of the trough. If you are lucky enough to still have the original submittals or plans for the clarifier you will be able to obtain critical measurements and information from them. If not, you will need to obtain measurements from some portion of the existing clarifier weir and trough so that a new fiberglass replacement can be ordered.Carefully measure and record all dimensions of the weir plate and trough. Be sure to obtain the length of each V-notch, its depth, and the spacing between each V-notch. Clarification weir plates are calculated for specific flow and water velocity, so a high level of care should be taken to properly duplicate the original design, to not compromise the performance.

Read More

Topics:

water treatment issues,

water treatment,

water plant,

weir plate,

weir tank

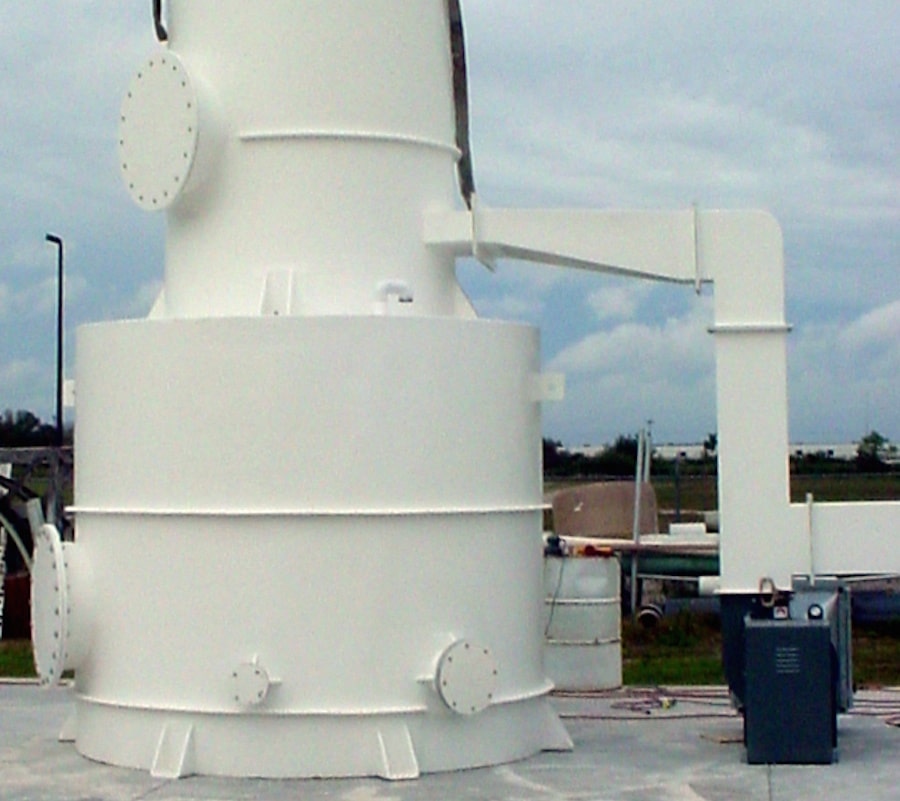

Maximizing Efficiency and Flow: Industrial Water Treatment with Degasification Systems

Industrial water treatment plays a critical role in maintaining water quality and ensuring the efficient operation of various processes. Degasification and decarbonation systems are essential components of such treatment methods. These systems effectively remove gases from the water, improving its quality and minimizing the risk of corrosion. However, when designing and installing degasification or decarbonation towers, it is important to consider hydraulic flow and system design. This blog post will explore the significance of proper hydraulic fundamentals in optimizing degasification systems, avoiding common pitfalls, and ensuring smooth water flow.

Optimizing Hydraulic Flow for Degasification Systems

Leveraging elevations can greatly benefit hydraulic flow when incorporating a degasification or decarbonation tower into an industrial water treatment system. For example, placing the tower on top of a large clear well or on a structural platform adjacent to the tank can optimize water movement. This strategic placement takes advantage of gravitational forces and enhances hydraulic efficiency.

However, applying sound hydraulic principles during the system design phase is crucial to prevent costly issues. Design professionals typically consider factors such as the size of the effluent fitting or pipe diameter and base their design on the length of the run and elevation. Failing to account for these factors can lead to hydraulic turbulence and improper water flow.

Preventing Tower Flooding and Hydraulic Turbulence

Improperly designed tower drainage systems can result in flow issues, leading to tower flooding. This occurs when water begins to vortex from the bottom of the tower due to a straight laminar pipe configuration. Vortex breakers such as the DI-VB100 series or other devices must be integrated into the tower design to avoid this. These breakers disrupt the vortex formation and promote smooth water flow.

Read More

Topics:

water treatment issues,

degasification,

water treatment

Read More

Topics:

water treatment issues,

water quality,

pH levels of water,

aeration,

water treatment,

advanced treatment solutions,

fiberglass,

About DeLoach Industries,

fabrication,

biological scrubber,

Chemical Odor,

media packing,

pH levels,

Decarbonation,

De-Aeration,

decarbonator,

boiler system,

distillation,

degasifier,

RO system,

H2S Degasifier,

Fish Farming,

Aquaculture,

Pisciculture,

Biological Odor Control Scrubber,

Biological odor control,

removal of CO2 from water,

Deagasification,

decarbonation of water,

Sand filters,

Filter Media,

municipal water systems,

greensand,

DeLoach Industries, Inc.,

Drinking Water

Ensuring Optimal Performance and Efficiency

When designing and installing a water treatment system, it is crucial to consider the hydraulic conditions that may arise when incorporating a degasification or aeration tower into the process. Hydraulic conditions can vary from one job to another, and the conditions created by a degasification tower are no exception. To optimize the performance and efficiency of the system, it is necessary to address potential issues such as vortex formation, increased suction on the effluent line, and water flow restrictions. In this blog post, we will explore the importance of incorporating vortex breakers, air relief valves, and anti-siphon valves to prevent hydraulic air locks and ensure the smooth operation of the degasification tower.

Preventing Hydraulic Air Locks in Degasification Towers

When a degasification tower is installed in a water treatment system, it is susceptible to hydraulic conditions that can lead to airlocks. These conditions primarily arise when the effluent drain line drops straight down for a significant distance. The resulting vortex effect causes the water to swirl, drawing air down the center and restricting the drainage of the tower. Additionally, the increased hydraulic flow and distance can create heightened suction on the effluent line, potentially causing flooding inside the degasification tower.

To avoid these issues, it is crucial to install vortex breakers inside degasification towers. Vortex breakers are specifically designed to disrupt the vortex formation, allowing for smooth water flow and preventing air locks. By strategically locating air relief valves and anti-siphon valves along the finish effluent pipeline of treated water, the risk of hydraulic air locks can be further minimized. These valves serve to release trapped air and prevent siphoning, ensuring optimal performance and preventing potential damage to the system.

Addressing Other Considerations: Decarbonation, Degasification, and Odor Control Scrubbers

Apart from preventing hydraulic airlocks, there are additional considerations in water treatment systems that warrant attention. Decarbonation is a process that removes carbon dioxide from water, particularly important in applications where low alkalinity and pH control are essential. Degasification, on the other hand, involves removing dissolved gases from water, often through the introduction of air or other methods like vacuum stripping or membrane degasification.

In certain cases, water treatment systems may also require odor-control scrubbers. These scrubbers effectively remove unpleasant odors caused by chemical reactions or the presence of certain compounds. By employing various techniques such as chemical adsorption or biological treatments, odor control scrubbers ensure the final treated water meets the desired olfactory standards.

When designing and installing a water treatment system, careful consideration must be given to the hydraulic conditions that may arise within a degasification or aeration tower. Incorporating vortex breakers, air relief valves, and anti-siphon valves into the system is crucial to prevent hydraulic air locks and ensure smooth operation. Furthermore, controlling alkalinity and pH, addressing water turbidity, and implementing decarbonation, degasification, and odor control measures are vital to optimizing the performance and efficiency of the water treatment system. By consulting professionals in the field, such as DeLoach Industries Inc., you can gain valuable insights and expertise to tailor your water treatment system to your specific needs and requirements.

Read More

Topics:

water treatment issues,

degasification,

water treatment

Industrial water treatment systems play a crucial role in maintaining the quality and sustainability of water used in various industrial processes. One of the key challenges faced by industries is the presence of dissolved gases, particularly carbon dioxide (CO2), and corrosive gases like hydrogen sulfide (H2S) in the water. These gases can have detrimental effects on equipment, cause pH imbalances, and even compromise the overall efficiency of industrial processes.

Read More

Topics:

water treatment issues,

water quality,

degasification,

water treatment,

decarbonator,

degasifier,

degassed water,

Deagasification,

decarbonation of water,

DeLoach Industries, Inc.,

Drinking Water,

DeLoach Industries,

water process system

When operating a forced or induced draft water treatment tower system it is important to properly maintain your distribution system.

The distribution system is a fundamental component for any type of unit: an Aerator, Degasifier, Scrubber, or Air Stripper. It must be designed and constructed with precision and accuracy. This will ensure its optimal performance throughout its lifetime.

It is essential that the distribution system undergo regular and thorough maintenance. This will ensure it can do its job effectively.

Maintenance should include cleaning and inspecting pipes and connections. Additionally, worn or damaged parts should be replaced or repaired. Lastly, test the entire system to ensure proper functioning.

Regular maintenance is essential. It helps to prevent costly breakdowns or failures. Additionally, it minimizes disruptions to the distribution system.

Regular maintenance helps the distribution system run efficiently. This leads to better, more reliable service for customers.

The key role of the distribution system is to properly distribute the water flow over the media bed. If the distribution system is designed incorrectly then water will not be properly distributed which can cause multiple problems.

The distributor can be damaged or fouled. When this happens, the water pattern is changed. This affects the flow rate across the media bed. This can lead to low or high hydraulic flood conditions in the media bed.It is important to inspect the distribution system within 30 days of the initial startup of a system. Then decide, based upon application, if the future inspections can be extended to 90 or 180 days.

Iron oxidation and H2S require more frequent cleaning of the distribution system than a degasifier used for CO2 removal. This is because they are more corrosive.

Read More

Topics:

water treatment issues,

water treatment,

water distribution system,

Aerator