Industrial Odor Control Scrubbers: Making the Right Choice for Your Water Treatment Process

Industrial odor control scrubbers play a crucial role in water treatment processes, ensuring the removal of harmful pollutants and unpleasant odors. When it comes to selecting the right scrubber for your specific needs, it's essential to have a thorough understanding of the requirements of your operation. In this article, we will explore the factors to consider and the key differences between chemical scrubbers and biological scrubbers. By the end, you'll be equipped with the knowledge to make an informed decision for your industrial water treatment system.

Before delving into the specifics of chemical and biological scrubbers, it's important to evaluate your water treatment process thoroughly. Asking the right questions will help you identify the critical factors that will influence your scrubber selection. Consider factors such as the motor system's operation and the loading rate of pollutants. By gaining a comprehensive understanding of your process, you can ensure that your chosen scrubber will effectively meet your water treatment needs.

The design process the most important thing is having a total understanding of the need for the scrubber to ensure you make the right decision. For this reason, always ask the right questions about your process such as how you are going to operate the motor system and what the loading rate is. When selecting an odor control scrubber you must take into consideration all of the variables of the project.

One example is the decision between Chemical Scrubbers and Biological Scrubbers. If there are a lot of variations and load rates then typically a Chemical Scrubber would be your best choice. A Biological Scrubber would not be the right choice because the biological bed is not able to adjust

quickly

enough to the increased load rate.

Chemical Scrubbers: A Versatile Solution for Varied Load Rates

Chemical scrubbers are known for their versatility and effectiveness across a wide range of load rates and variations. These scrubbers utilize chemical reactions to neutralize and remove pollutants from the air emissions. When the loading rate of pollutants fluctuates significantly, chemical scrubbers are an ideal choice due to their ability to adjust quickly. By employing various chemical agents and processes, these scrubbers can effectively control odors and remove harmful substances from the air.

Biological Scrubbers: Harnessing the Power of Nature

While chemical scrubbers excel in managing varied load rates, biological scrubbers offer a different approach to industrial odor control in water treatment. Biological scrubbers utilize living microorganisms to break down and eliminate pollutants. This process, known as biofiltration, relies on the natural ability of microorganisms to metabolize and convert pollutants into harmless byproducts. However, it's important to note that biological scrubbers are not suitable for applications with significant variations in load rates. The biological bed in these scrubbers requires time to adjust to increased load rates, making them less adaptable in such scenarios.

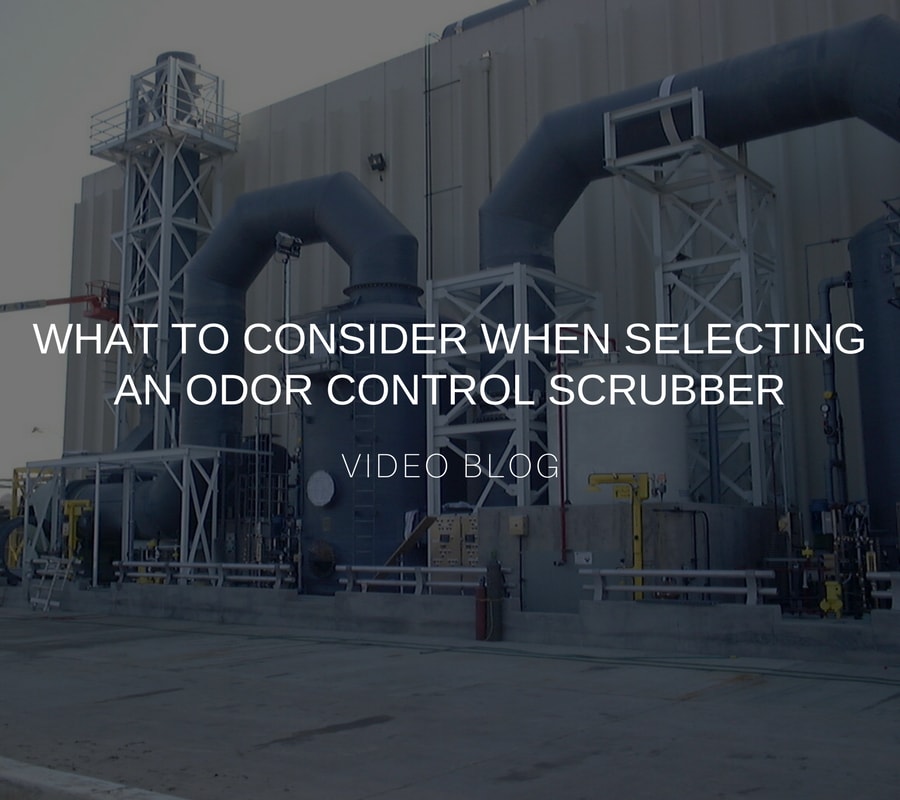

DeLoach Industries: Your Trusted Partner for Odor Control Scrubbers

When it comes to finding the right odor control scrubber for your water treatment application, DeLoach Industries is a name you can trust. With a wide range of scrubbers designed for both municipal and industrial markets, DeLoach Industries offers complete package systems tailored to meet your specific needs. Their professional design team can provide expert guidance and support throughout the selection and implementation process, ensuring optimal performance and efficiency.